Cylindrical Roller Bearing

Payment Terms:

T/T

100% L/C

Cash

Western Union

Delivery Time:

30 Days

Keywords:

Series:

Product Details

Cylindrical Roller Bearing

The rollers of cylindrical roller bearings are usually guided by two ribs of a certain ring, and the cage, roller and guide ring form an assembly that can be separated from another ring, which is a separable bearing.

This type of bearing is more convenient to install and disassemble, especially when the inner and outer rings are required to have an interference fit with the shaft and shell. Such bearings are generally only used to bear radial loads, and only single-row bearings with ribs on the inner and outer rings can bear small constant axial loads or large intermittent axial loads.

Compared with deep groove ball bearings of the same external dimensions, these bearings have a larger radial load capacity. However, the machining accuracy requirements for shafts, housing holes and other related parts that cooperate with such bearings are relatively high.

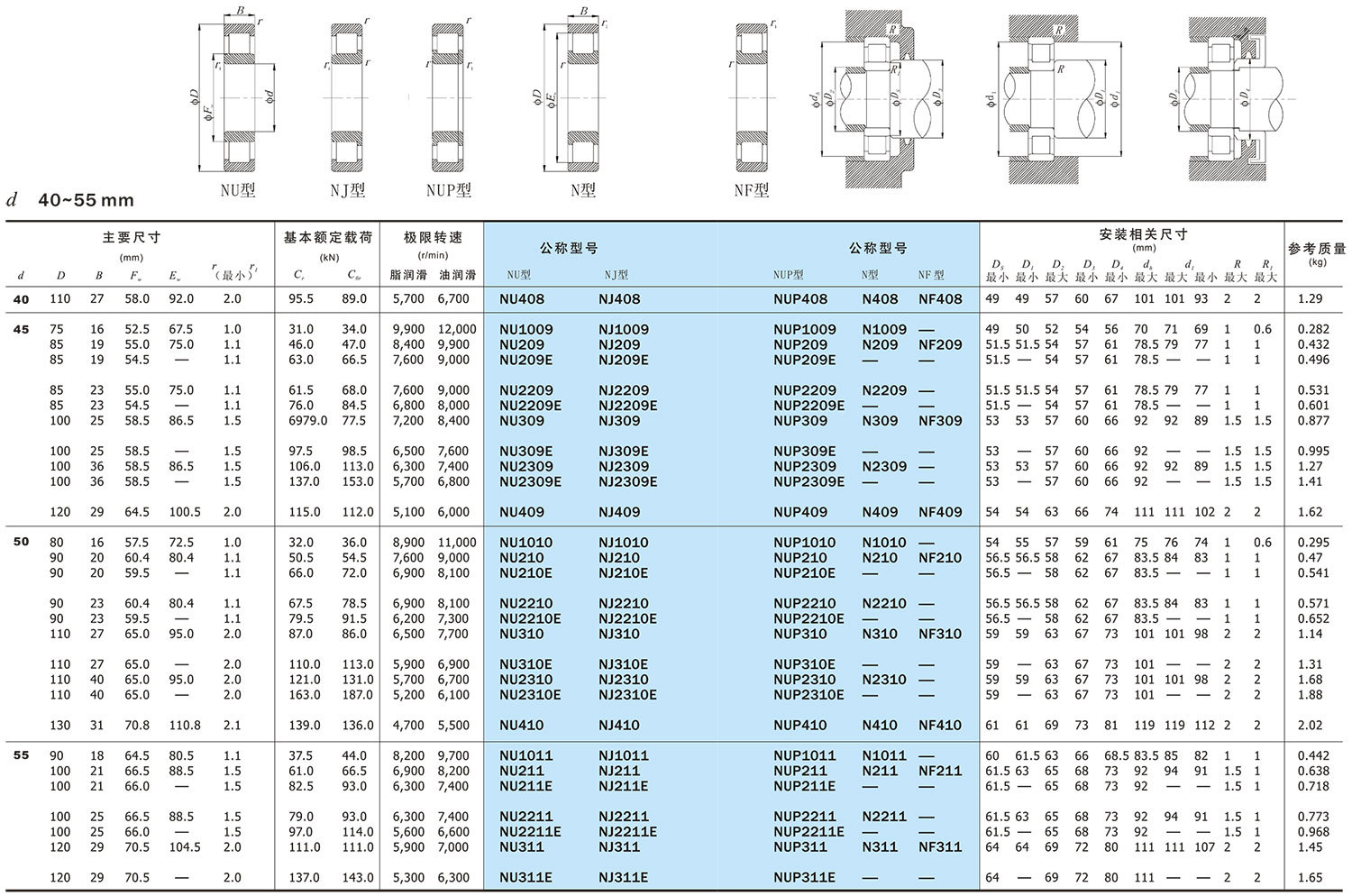

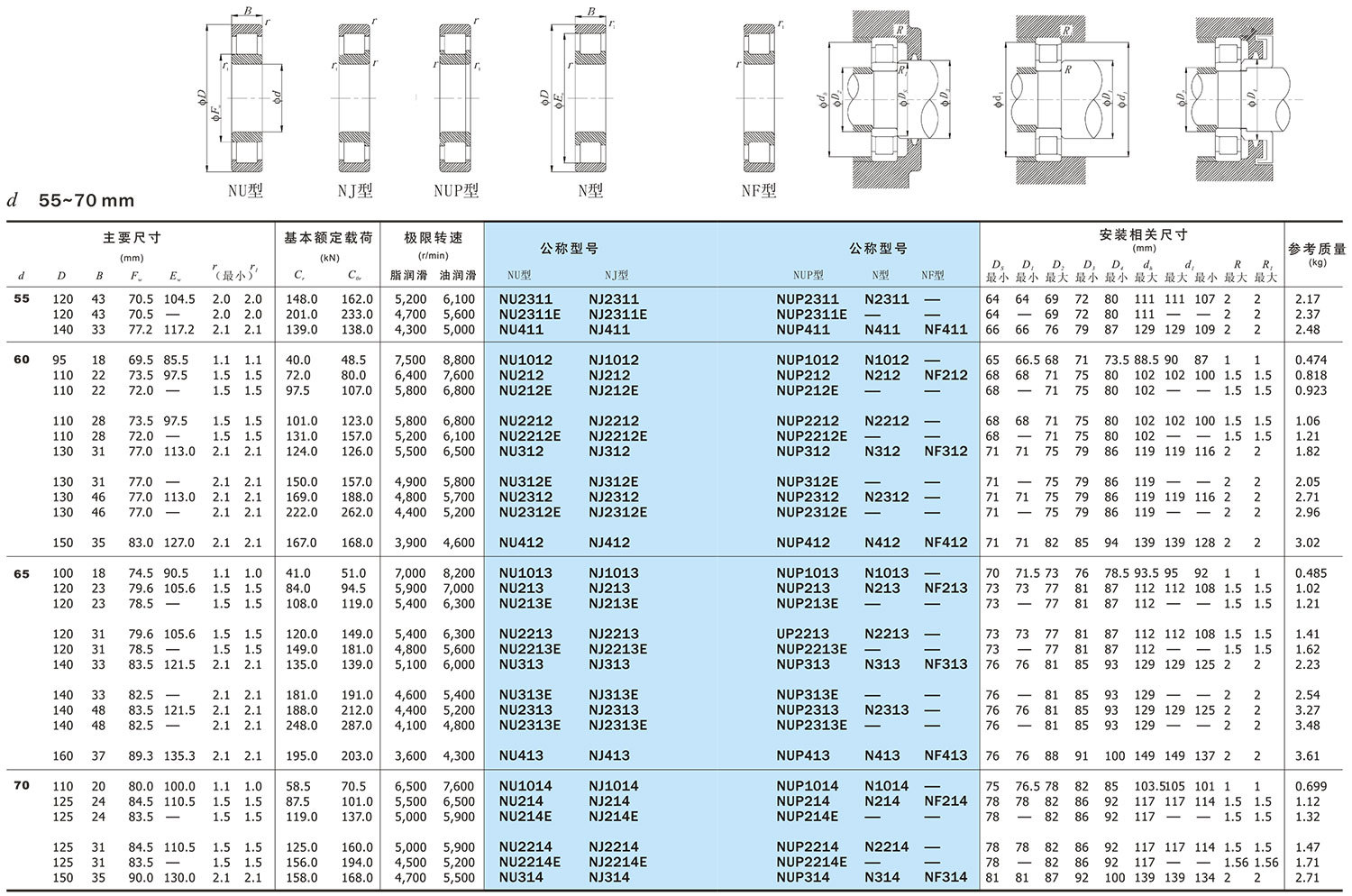

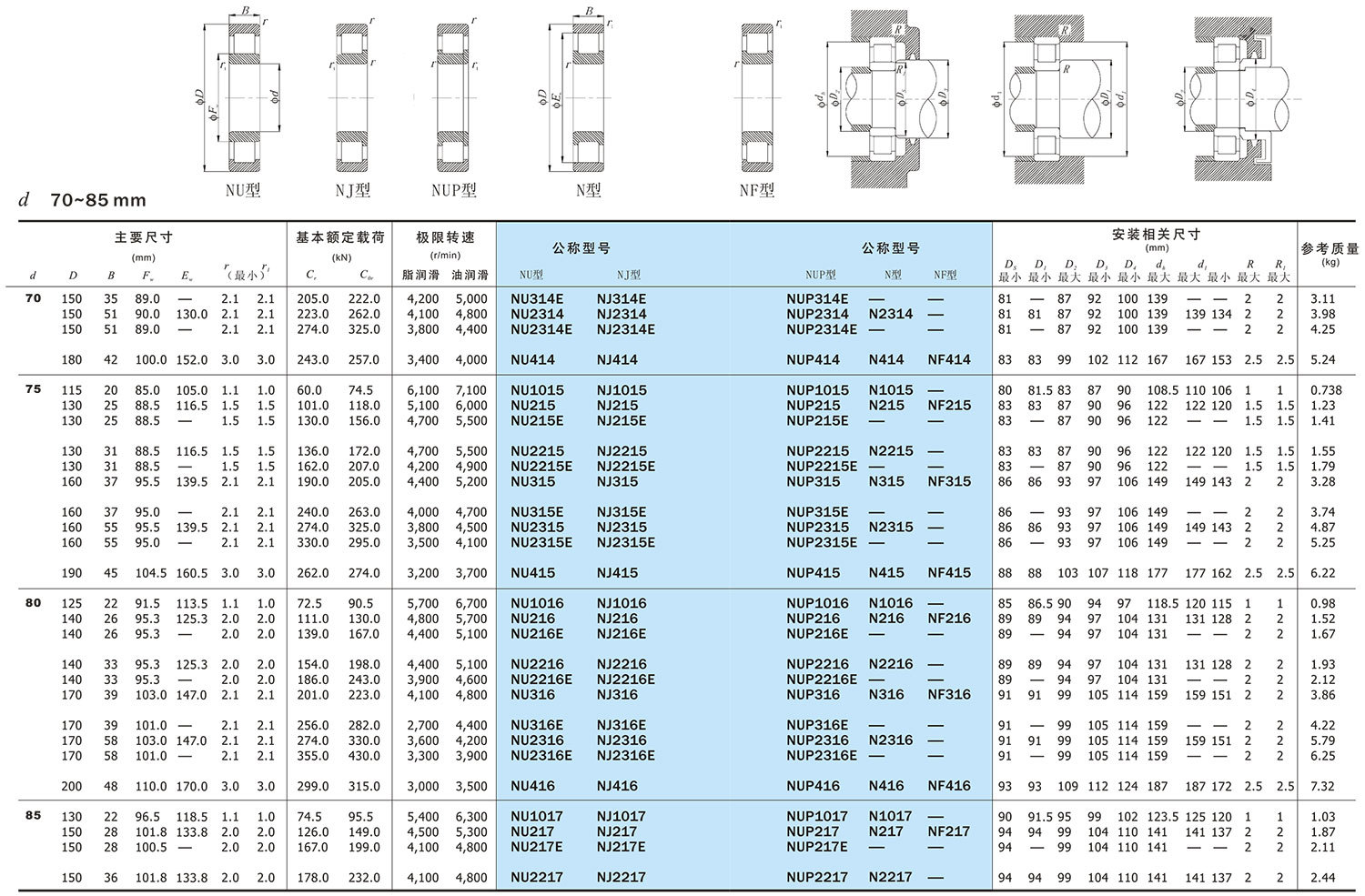

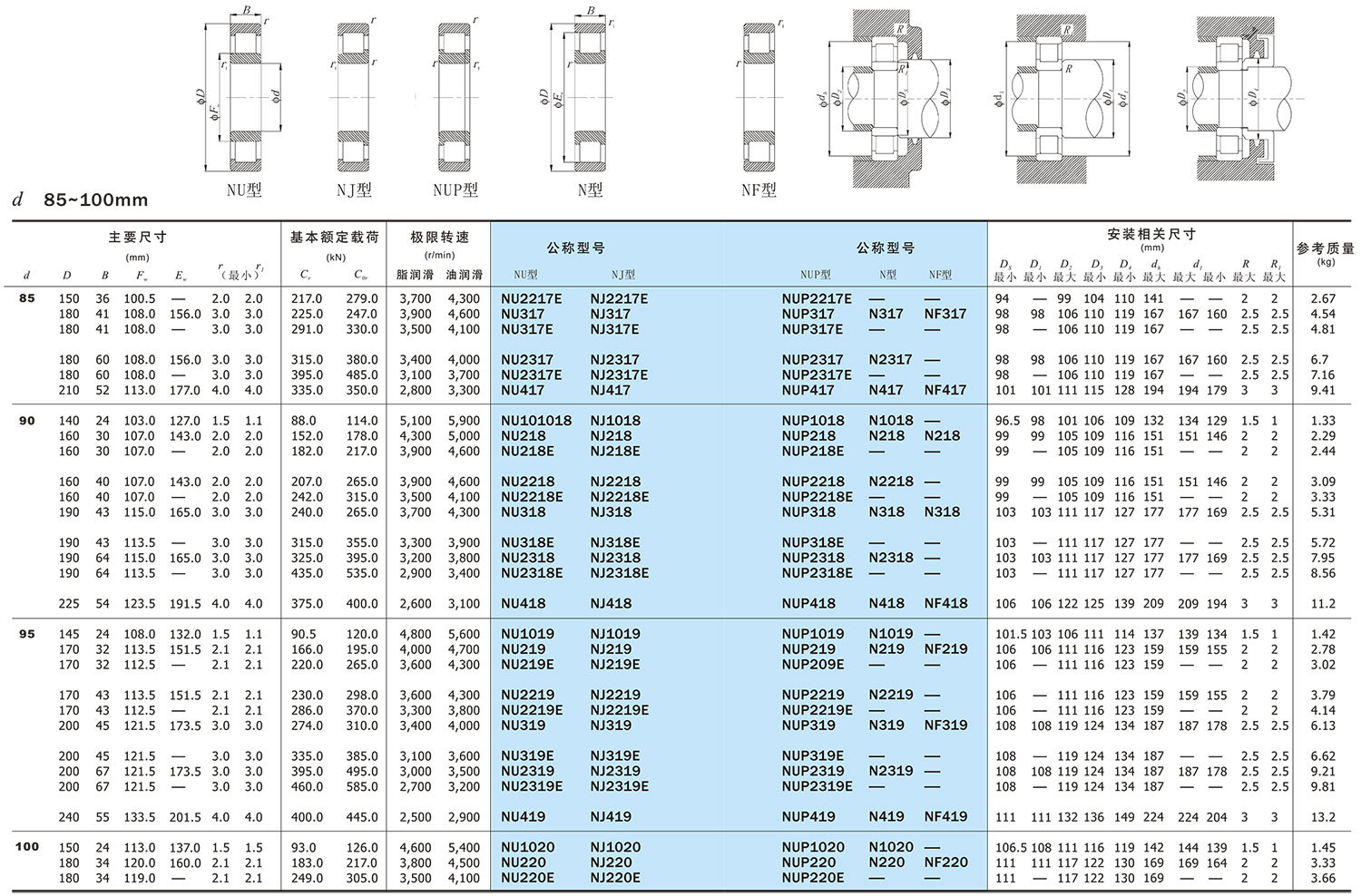

1. Main structure type

|

No ribs on the outer ring, double ribs on the inner ring Type N |

Double ribs on the outer ring, single rib on the inner ring NJ type |

NU type with double ribs on the outer ring and no ribs on the inner ring |

Double ribs on the outer ring, single rib on the inner ring with one piece NUP type |

Outer ring single rib, inner ring double rib NF type |

The cages of the above structure bearings generally include: stamping structure, nylon structure, etc., and some models can also be full complement roller structure without cage.

2. Allowable inclination angle

Cylindrical roller bearings generally do not allow the shaft to tilt relative to the housing bore. However, for single row cylindrical roller bearings, under light load conditions, the inner and outer rings are allowed to incline 2' to each other in the axial direction. If the load is large, the allowable error is slightly larger, but not more than 4'.

3. Tolerance and clearance

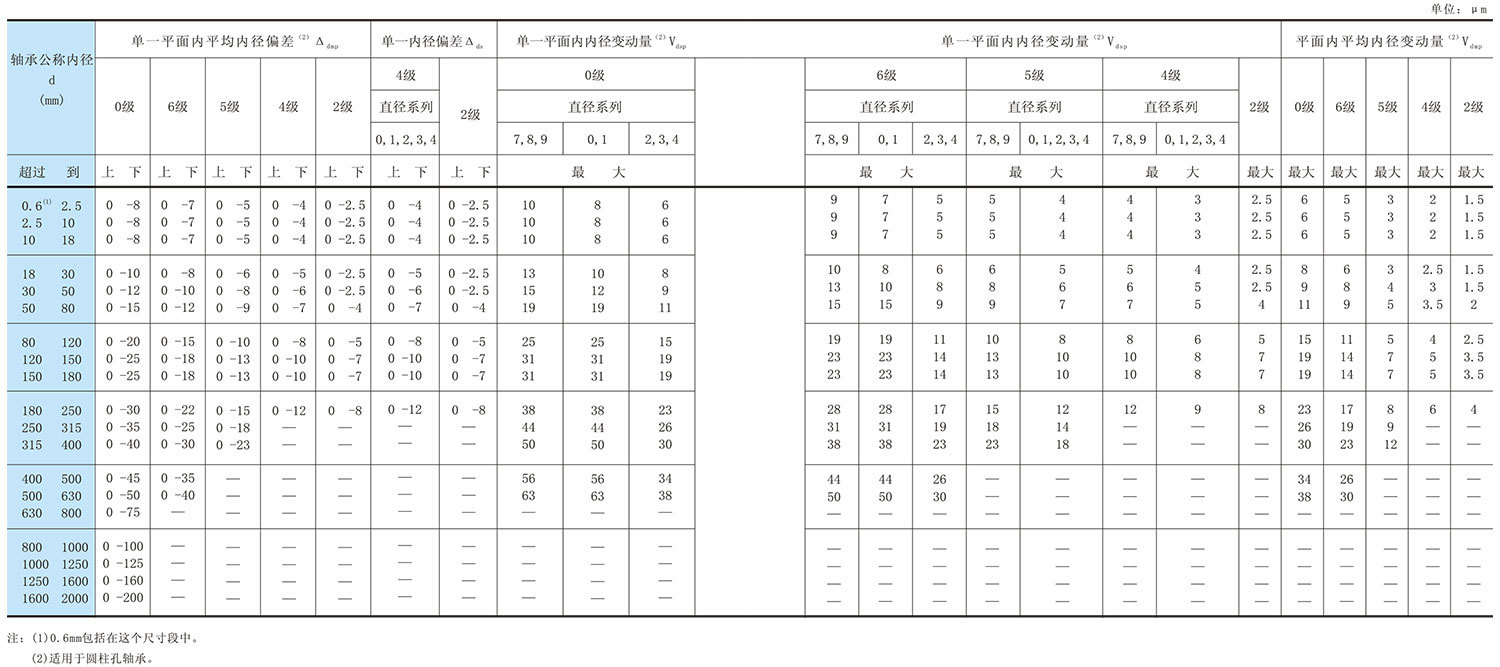

Products with different tolerance classes can be provided according to the needs, and the tolerance values are shown in the previous tolerance section.

4. Axial load capacity

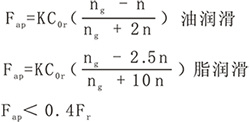

For cylindrical roller bearings with ribs on the inner and outer rings, the axial load it bears is related to the radial load it bears and the lubrication method. The maximum permissible axial load is:

in the formula;

Fᵃᵖ: maximum allowable axial load N

K: Coefficient related to the bearing dimension series

For 2 and 3 series K=0.2

22, 23 series K=0.16

C₀ᵣ: radial static load rating of the bearing N

nᵍ: The limit speed when the bearing bears pure radial load. When the radial load Fᵣ>0.1Cᵣ, the limit speed listed in the dimension table should be multiplied by the reduction factor r/min

n: bearing operating speed r/min

The axial load determined by the above formula can make 0-level tolerance bearings (except improved structure and reinforced bearings) work normally under the following conditions:

The bearing temperature rise is 55°C for oil lubrication, 40°C for grease lubrication, and the maximum bearing temperature is 90°C (the viscosity of the lubricating oil used is Vs=30mm²/s, and the dropping point of the grease is 170°C).

If the axial load acts intermittently, the allowable axial load can be doubled, and it can be doubled when it acts temporarily. Single row cylindrical roller bearings with larger axial load capacity can be provided according to the working conditions.

5. Radial Equivalent Dynamic Load

Pᵣ=Fᵣ

For cylindrical roller bearings subjected to axial load

2, 3 series:

Pᵣ=Fᵣ+0.3Fₐ

Pᵣ=0.94Fᵣ+0.8Fₐ

22、23 series:

Pᵣ=Fᵣ+0.2Fₐ

Pᵣ=0.94Fᵣ+0.53Fₐ (0≤Fₐ/Fᵣ≤0.12) (0.12≤Fₐ/Fᵣ≤0.3)

6. Radial equivalent static load

P₀ᵣ=Fᵣ

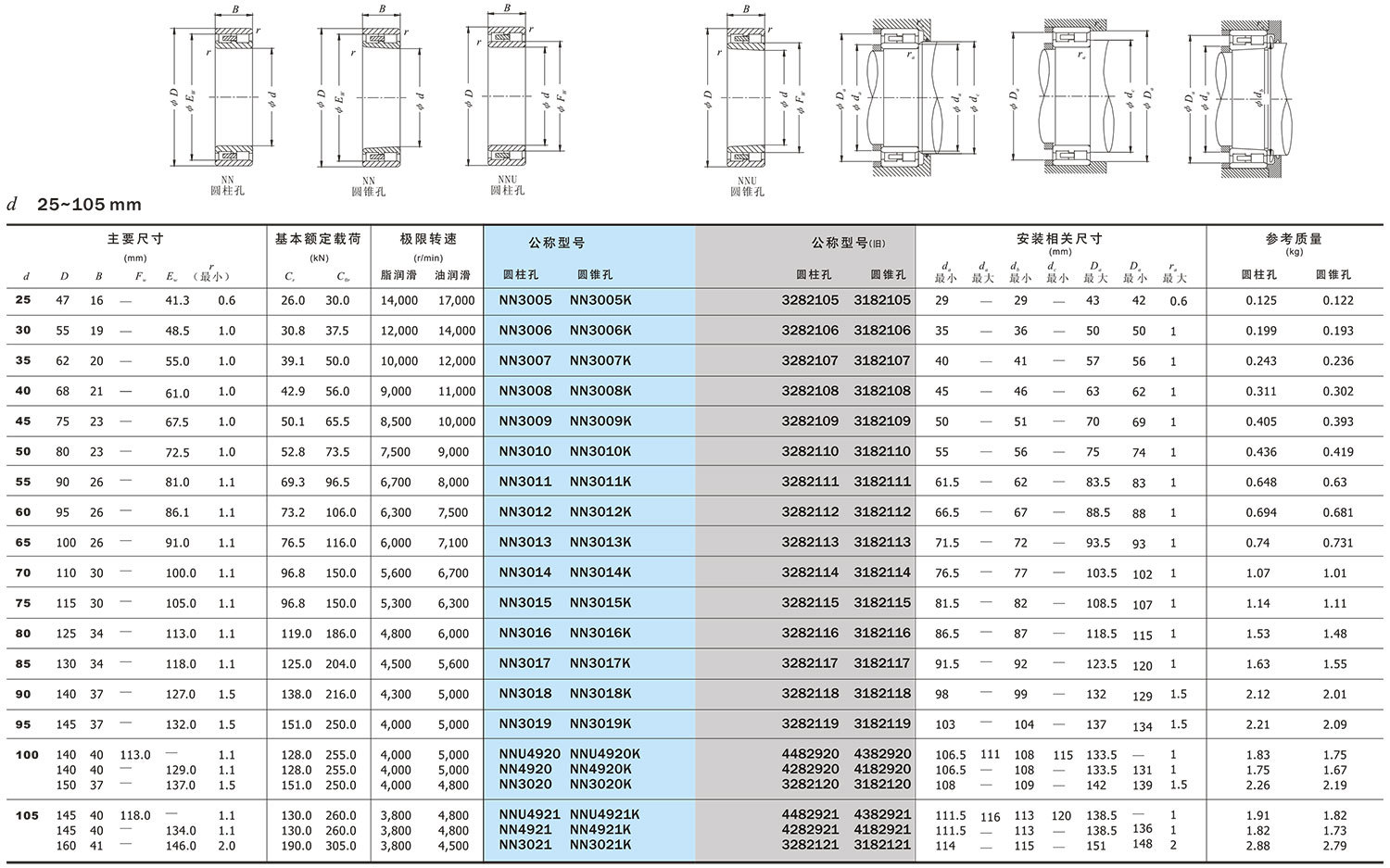

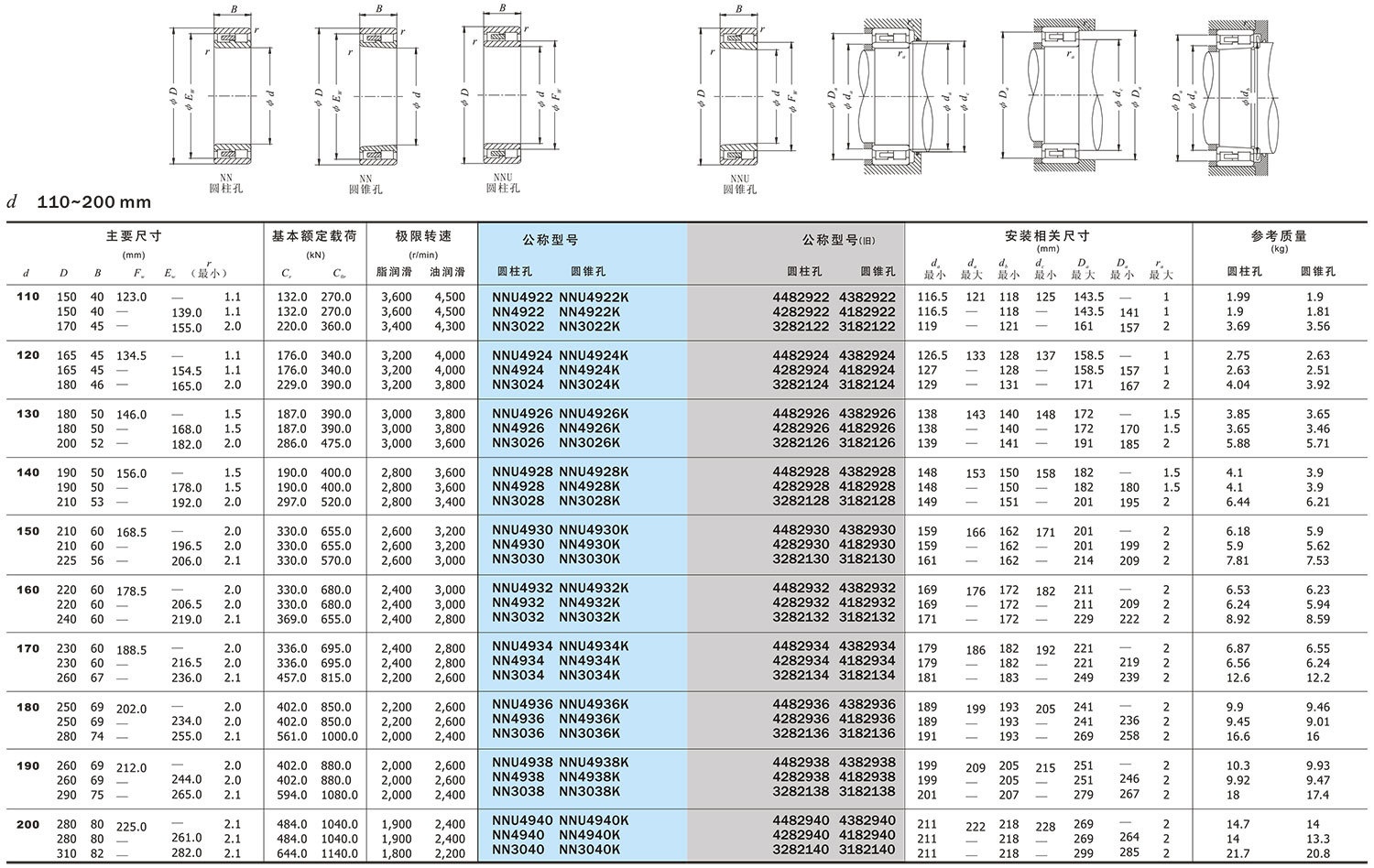

Double Row Cylindrical Roller Bearings

Double row cylindrical roller bearings are characterized by small cross section, high load capacity and high rigidity. Mainly used in machine tools, rolling mill stands, plastic rollers, grinding machines and large gearboxes, etc.

C&U mainly produces NN and NNU double row cylindrical roller bearings. The separate rings and components of this type of bearing can be installed separately. The outer ring, roller and cage assembly of the NNU type double row cylindrical roller bearing can be installed separately from its inner ring, or all parts can be installed separately, which is convenient for bearings. installation, inspection and maintenance.

Double row cylindrical roller bearings have two types of inner diameters: cylindrical bore and tapered bore. The NN and NNU bearings produced by C&U provide two types with cylindrical bore and tapered bore. When mounting bearings with a tapered bore, it is possible to achieve a certain radial internal clearance or a certain preload.

Some double row cylindrical roller bearings have lubricating oil grooves or lubricating oil holes in the outer ring. C&U can provide double-row cylindrical roller bearings with lubricating oil grooves and lubricating oil holes in the outer ring. Double-row cylindrical roller bearings with lubricating oil grooves and lubricating oil holes are not listed in the dimension table. Center Consulting.

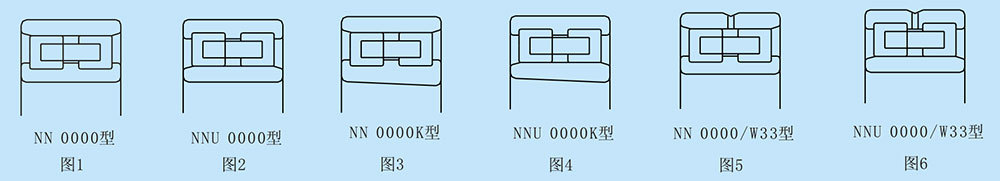

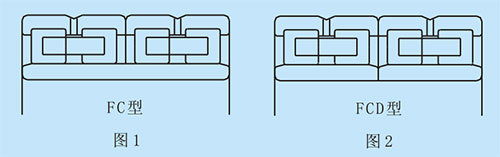

1. Structural form

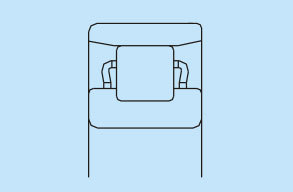

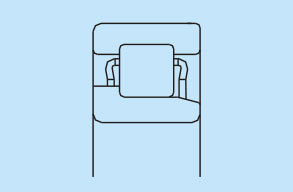

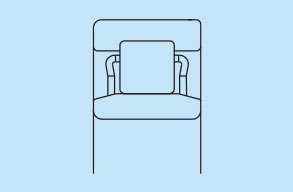

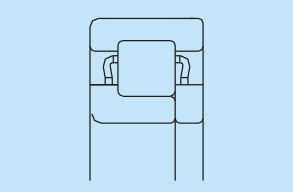

1. NN 0000 type (Figure 1): the inner ring has ribs, the outer ring has no ribs, and the inner diameter is a cylindrical hole;

2. NNU 0000 type (Figure 2): the inner ring has no ribs, the outer ring has ribs, and the inner diameter is a cylindrical hole;

3. NN 0000K type (Figure 3): the inner ring has ribs, the outer ring has no ribs, the inner diameter is a tapered hole, and the taper is 1:12;

4. NNU 0000K type (Figure 4): the inner ring has no ribs, the outer ring has ribs, the inner diameter is a tapered hole, and the taper is 1:12;

5. NN 0000/W33 type (Figure 5): the inner ring has ribs, the outer ring has no ribs, the inner diameter is a cylindrical hole, and the outer ring has lubricating oil grooves and lubricating oil holes;

6. NNU 0000/W33 type (Figure 6): The inner ring has no ribs, the outer ring has ribs, and the inner diameter is a cylindrical hole; the outer ring has lubricating oil grooves and lubricating oil holes.

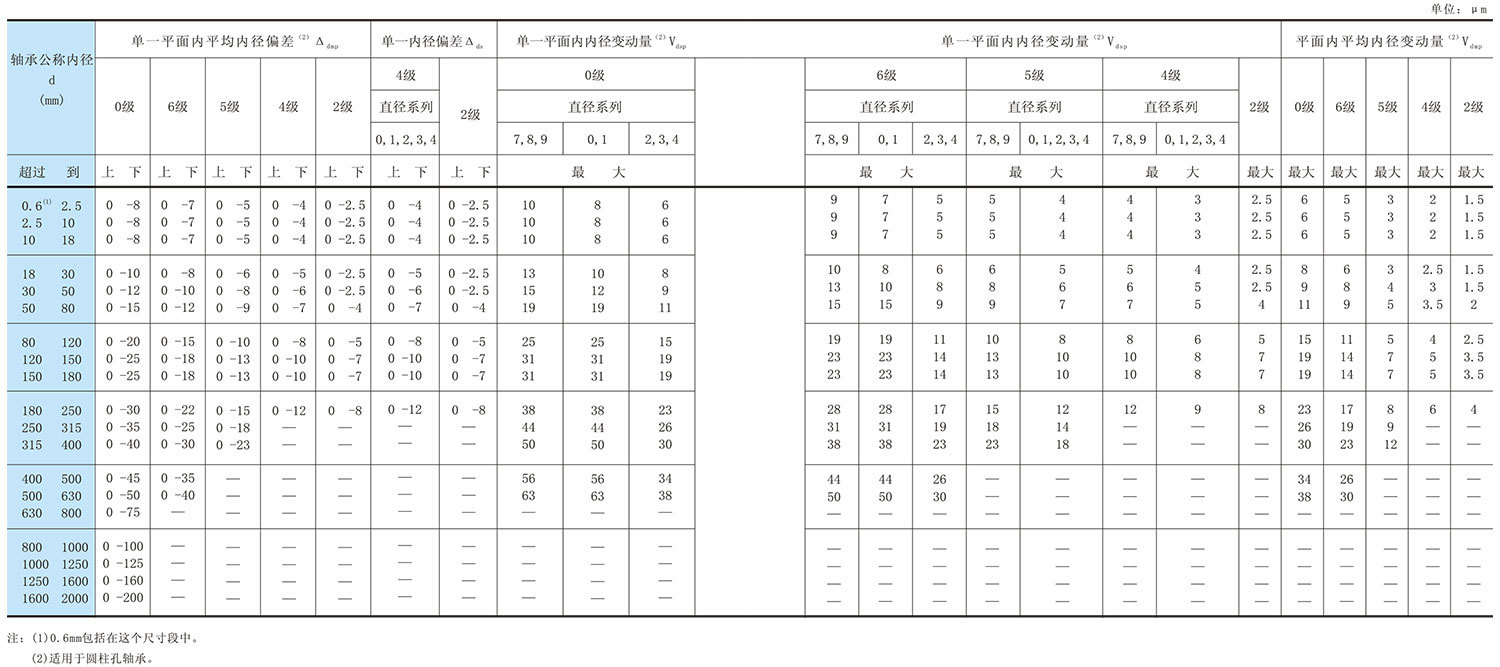

2. Dimensional accuracy and rotation accuracy

Tolerances for radial bearings (except tapered roller bearings)

3. Radial clearance

Recommended Radial Clearance of Double Row Cylindrical Roller Bearings

|

Bearing Nominal Inner Diameter d(mm) |

Cylindrical hole(μm) |

Conical hole(μm) |

|||||||||

|

1 set |

2 set |

1 set |

2 set |

3 set |

|||||||

|

Exceed |

Arrive |

The smallest |

Maximum |

The smallest |

Maximum |

The smallest |

Maximum |

The smallest |

Maximum |

The smallest |

Maximum |

|

24 |

24 |

10 |

20 |

20 |

30 |

5 |

15 |

10 |

20 |

20 |

30 |

4. Cage

Double-row cylindrical roller bearings generally use machine-made brass solid cages.

5. Equivalent dynamic load

P=Fᵣ

6. Equivalent static load

P₀=Fᵣ

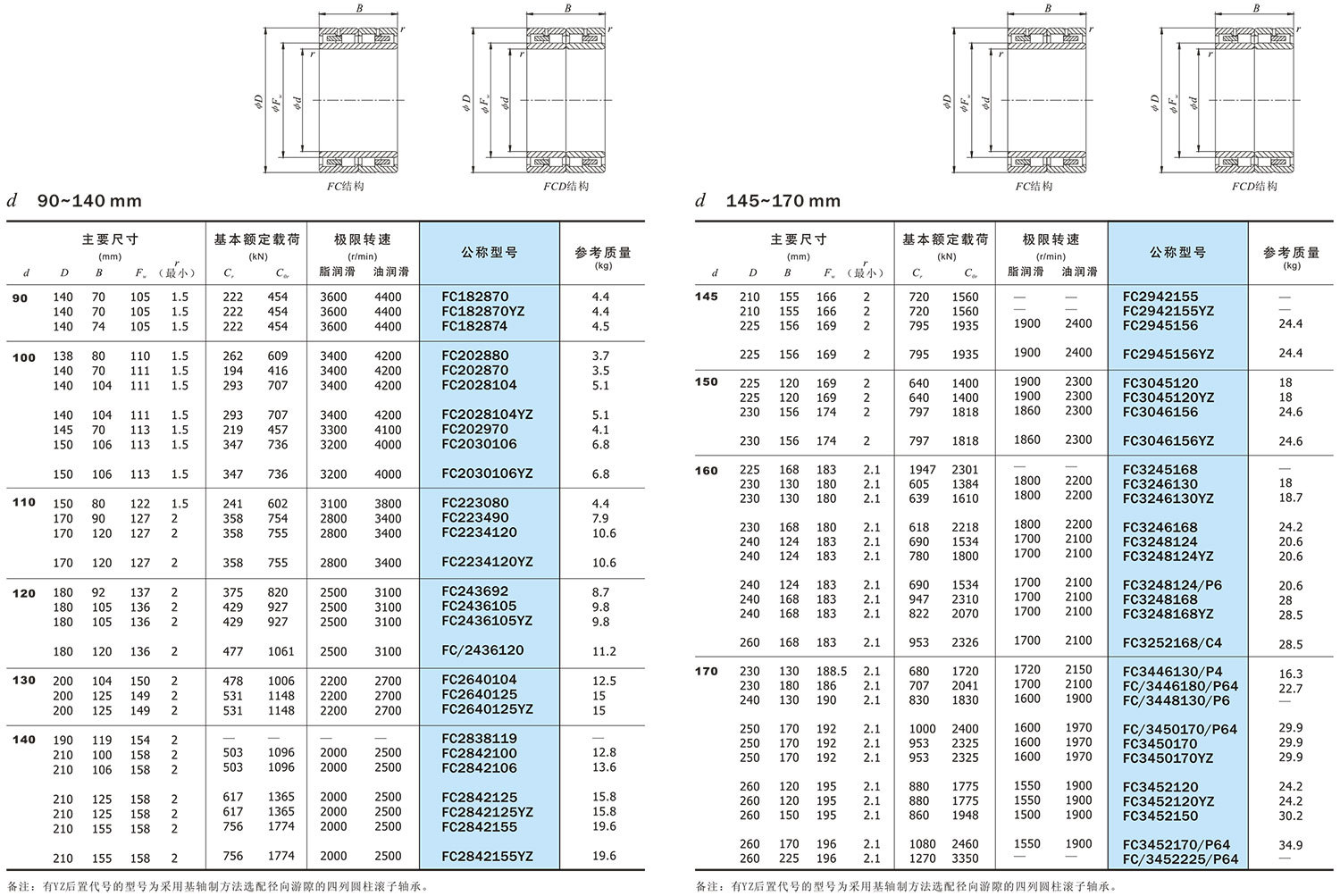

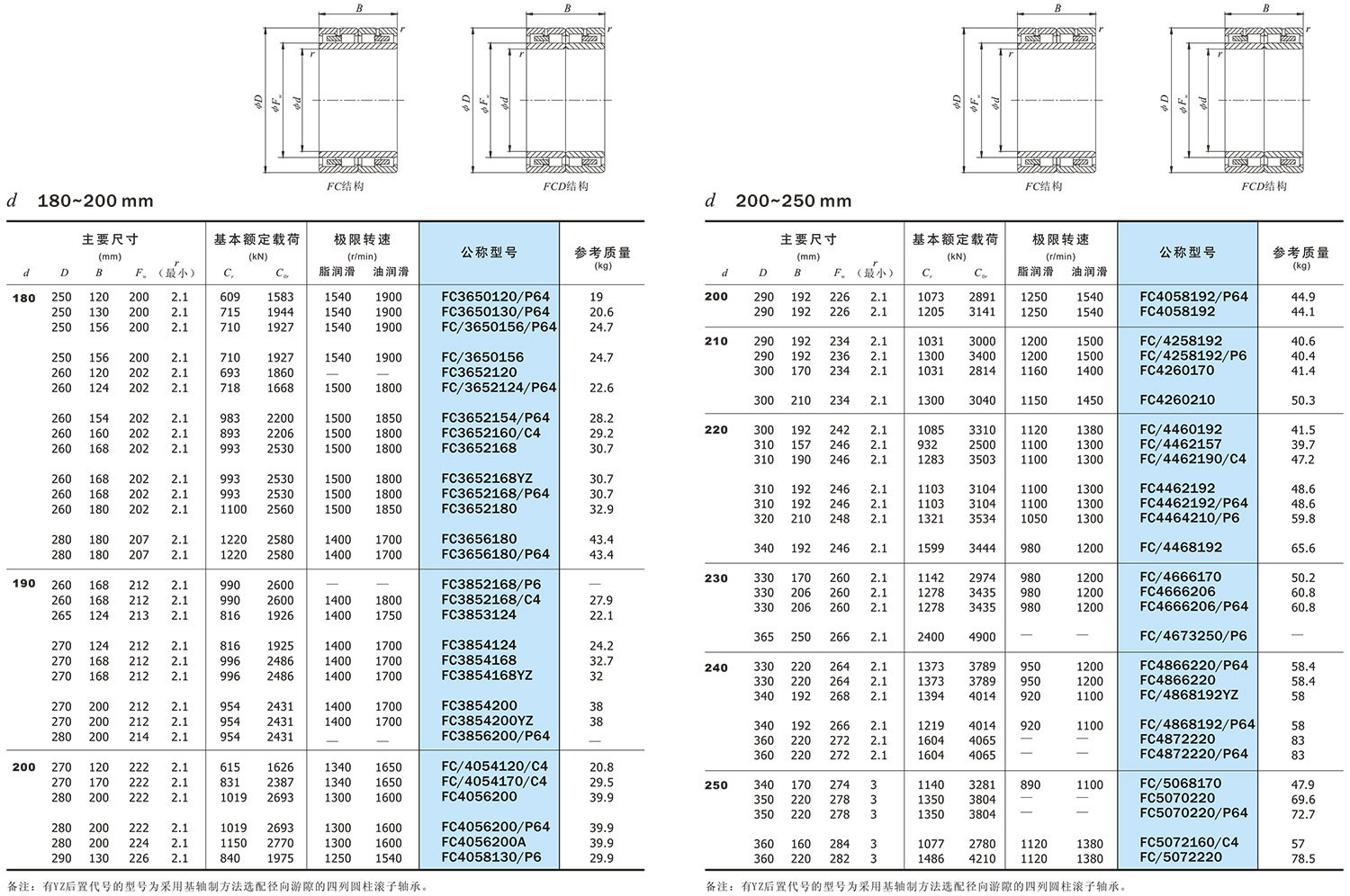

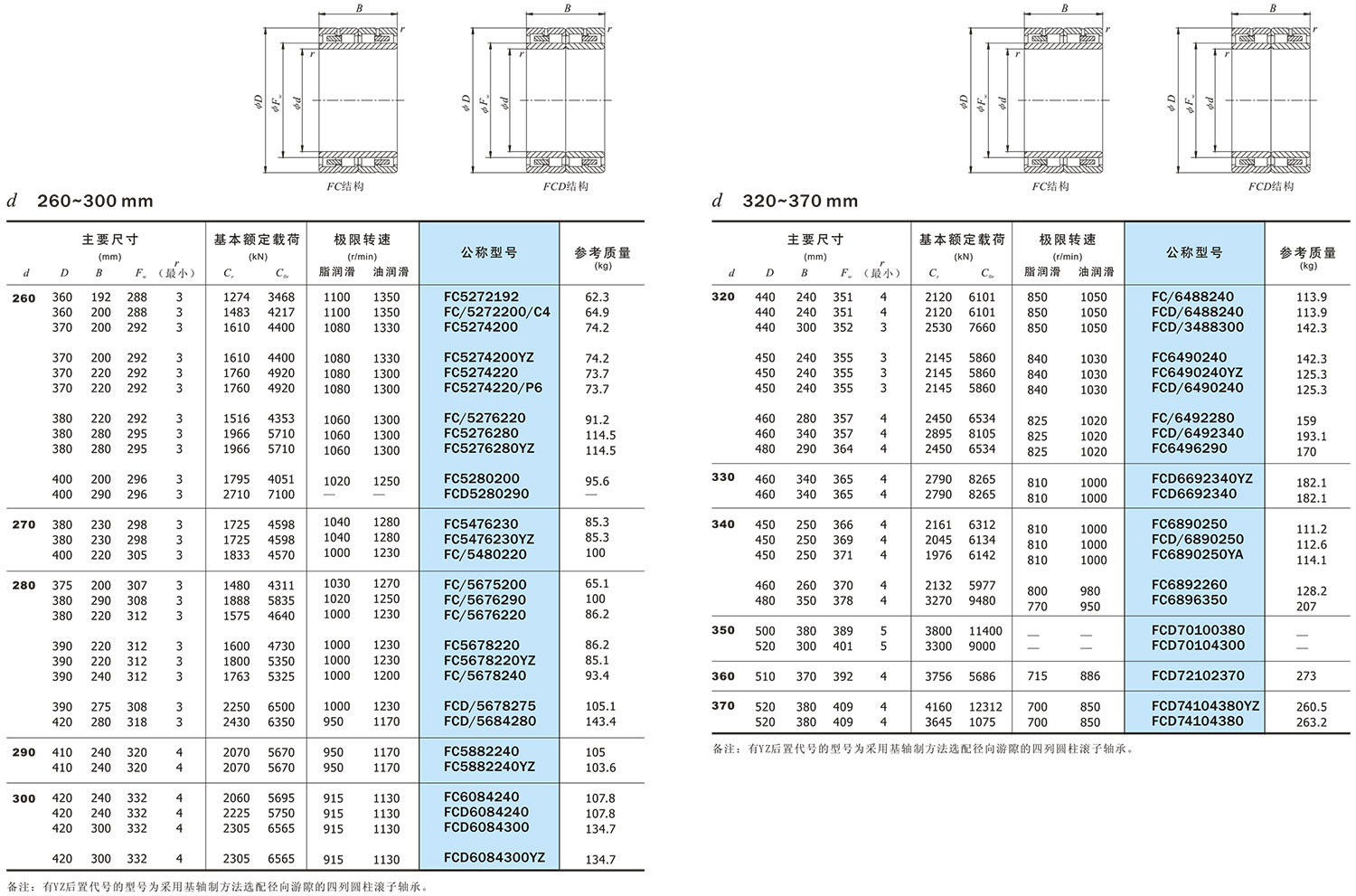

Four Row Cylindrical Roller Bearings

Four-row cylindrical roller bearings have the characteristics of simple structure, high precision, and large dynamic load rating, but they cannot bear axial loads. Since the inner ring has no ribs, the inner ring and outer ring sets (with a complete set of rollers and cages) can be installed separately, so it has the advantage of convenient installation and disassembly, so it is a cold and hot rolling steel mill with frequent replacement of various rolls. required products.

1. Structural form

1. FC type (Fig. 1): Two outer rings with ribs, a complete set of rollers and cage outer ring sets and one inner ring set;

2. FCD type (Figure 2): Two outer rings with ribs, a complete set of rollers and cages for the outer ring set and two inner rings are set.

2. Dimensional accuracy and rotation accuracy

Tolerances for radial bearings (except tapered roller bearings)

3. Radial clearance

As a roll radial support bearing, its working conditions are very harsh. The actual clearance during work is related to the bearing load, rotational speed, lubrication, temperature rise, design structure, mating surface roughness and interference fit of the inner diameter of the bearing. When selecting, the appropriate radial clearance should be selected according to the specific situation.

C3 group clearance is recommended for cold rolling mills or bearings with small inner diameter fit interference, and C4 group clearance is recommended for hot rolling mills or bearings with large inner diameter fit interference.

Radial clearance of four row cylindrical roller bearings (Cylindrical hole)

|

Bearing Nominal Inner Diameter d(mm) |

Clearance (μm) |

||||||||||

|

2 set |

0 set |

3 set |

4 set |

5 set |

|||||||

|

Exceed |

Arrive |

The smallest |

Maximum |

The smallest |

Maximum |

The smallest |

Maximum |

The smallest |

Maximum |

The smallest |

Maximum |

|

80 |

100 |

15 |

50 |

50 |

85 |

75 |

110 |

105 |

140 |

155 |

190 |

4. Cage

Four-row cylindrical roller bearings generally use machined brass solid cages.

5. Equivalent dynamic load

P=Fᵣ

6. Equivalent static load

P₀=Fᵣ

Split Cylindrical Roller Bearings

Due to the limitation of its own structure in many mechanical equipment, there are difficulties in the assembly and disassembly of integral bearings, inconvenient maintenance and replacement, especially when using large and extra-large bearings.

The series of split bearings developed by the Technology Center of Renben Group solves this problem, which greatly facilitates the loading and unloading of the bearings and reduces the production cost.

1. Application fields of split bearings

Split bearings can be used in all industrial fields, and can be used in all occasions where the installation of bearings is limited, such as various crankshafts, multi-support shafts, shaft shafts, and long shafts with several support positions.

- Cooling bed on rolled steel

- Converter

- Continuous casting machine

- Conveying equipment

- Lifts and conveyors

- Paper Machinery

- Raw material handling equipment

- Rotary kiln drive equipment

2. Comparison of the use of split bearings and integral bearings

- Easy to install

- Minimal equipment downtime

- No need to disassemble related devices

3. Structural characteristics of split cylindrical roller bearings

a. The inner ring, outer ring and cage are all divided into two semicircular parts by splitting

b. The inner diameter surface is Cylindrical hole, which can be directly installed on the shaft

c. Integral bearings can be replaced

4. Advanced Technology of Split Cylindrical Roller Bearings

The split cylindrical roller bearing adopts advanced bearing production technology to ensure the safe operation of the bearing:

a. Finite element analysis, CAD optimization design, to obtain the maximum rated load bearing structure parameters

b. Advanced cutting technology and cutting scheme

c. Advanced heat treatment technology to obtain excellent intrinsic quality

d. The smallest fastener design that ensures reliable connection and is ingenious and reasonable

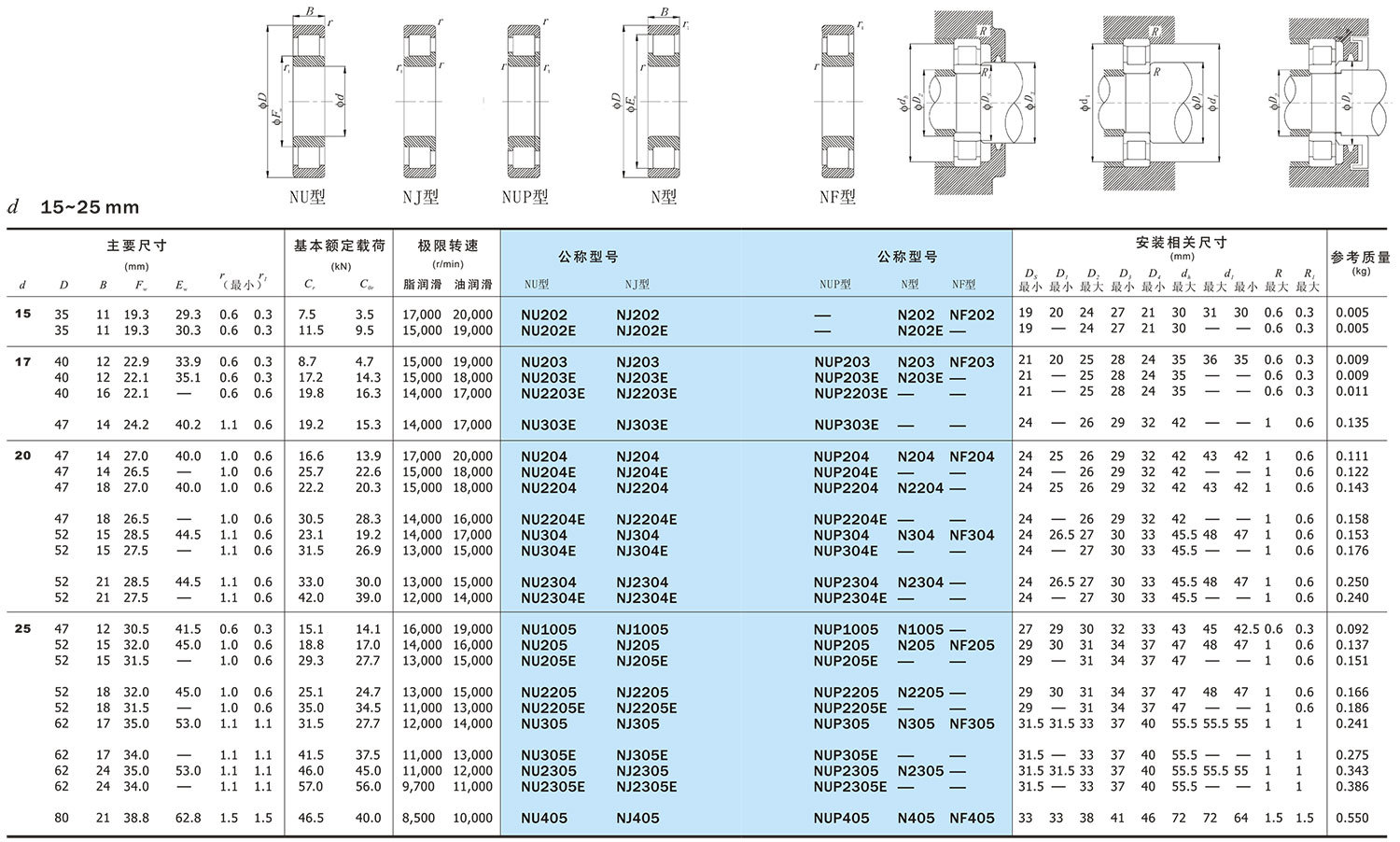

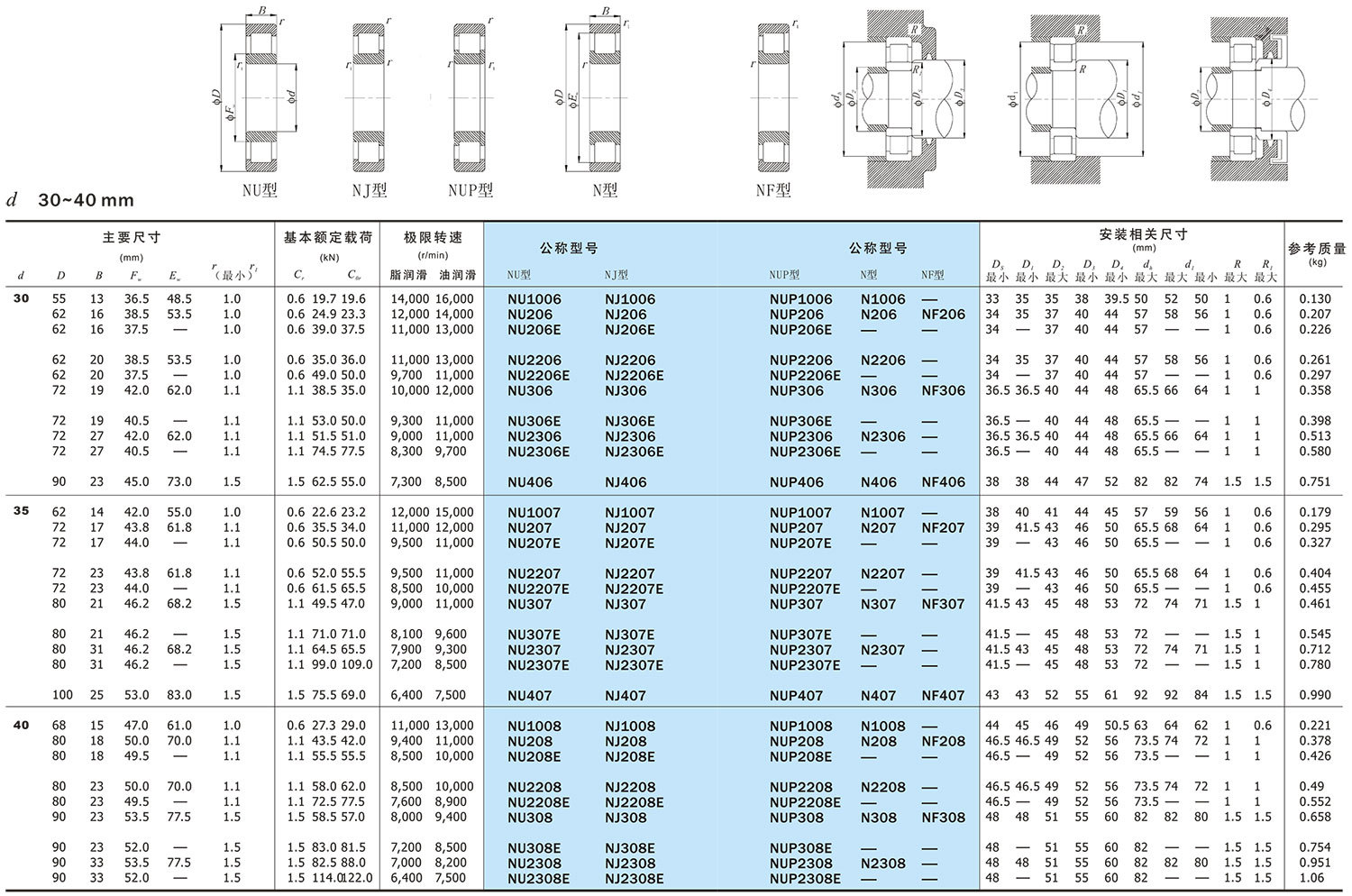

Single Row Cylindrical Roller Bearings

Double Row Cylindrical Roller Bearings

Four Row Cylindrical Roller Bearings

Type

Inside Diameter(mm)

Outside Diameter(mm)

Breadth(mm)

Weight(g)

Dynamic Load(N)

Static Load(N)

Supply From Stock

-

-

-

-

-

-

-

-

Factory

Previous Article

Next Article

Previous Article

Next Article

FAQ

Q

Are you a manufacturer?

A

Yes, we are a strong manufacturer.

Q

Can we visit your factory?

A

Of course, welcome to our factory for on-site inspection.

Q

Can we order samples?

A

Yes, we support customization.

Q

Can you arrange shipment? What are the physical methods?

A

Yes Can be arranged by sea shipping.

Q

What is your lead time?

A

Within 30 days after we confirm your request .

Q

What payment methods do you support?

A

T/T, 100% L/C at sight, Cash, Western Union are all accepted if you have other payment,please contact me.

Get a Free Quote

Series of Products