Deep Groove Ball Bearing

Payment Terms:

T/T

100% L/C

Cash

Western Union

Delivery Time:

30 Days

Keywords:

Series:

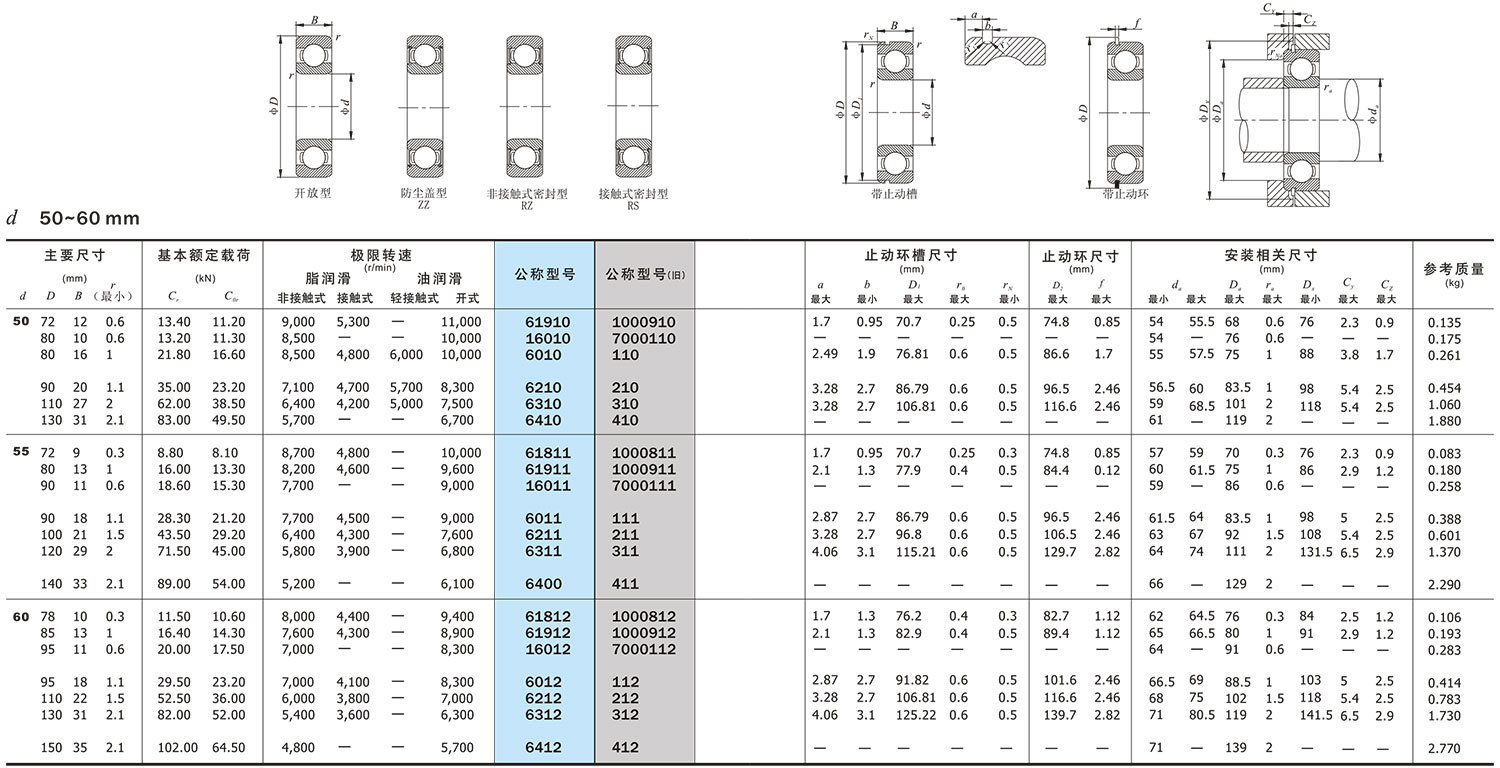

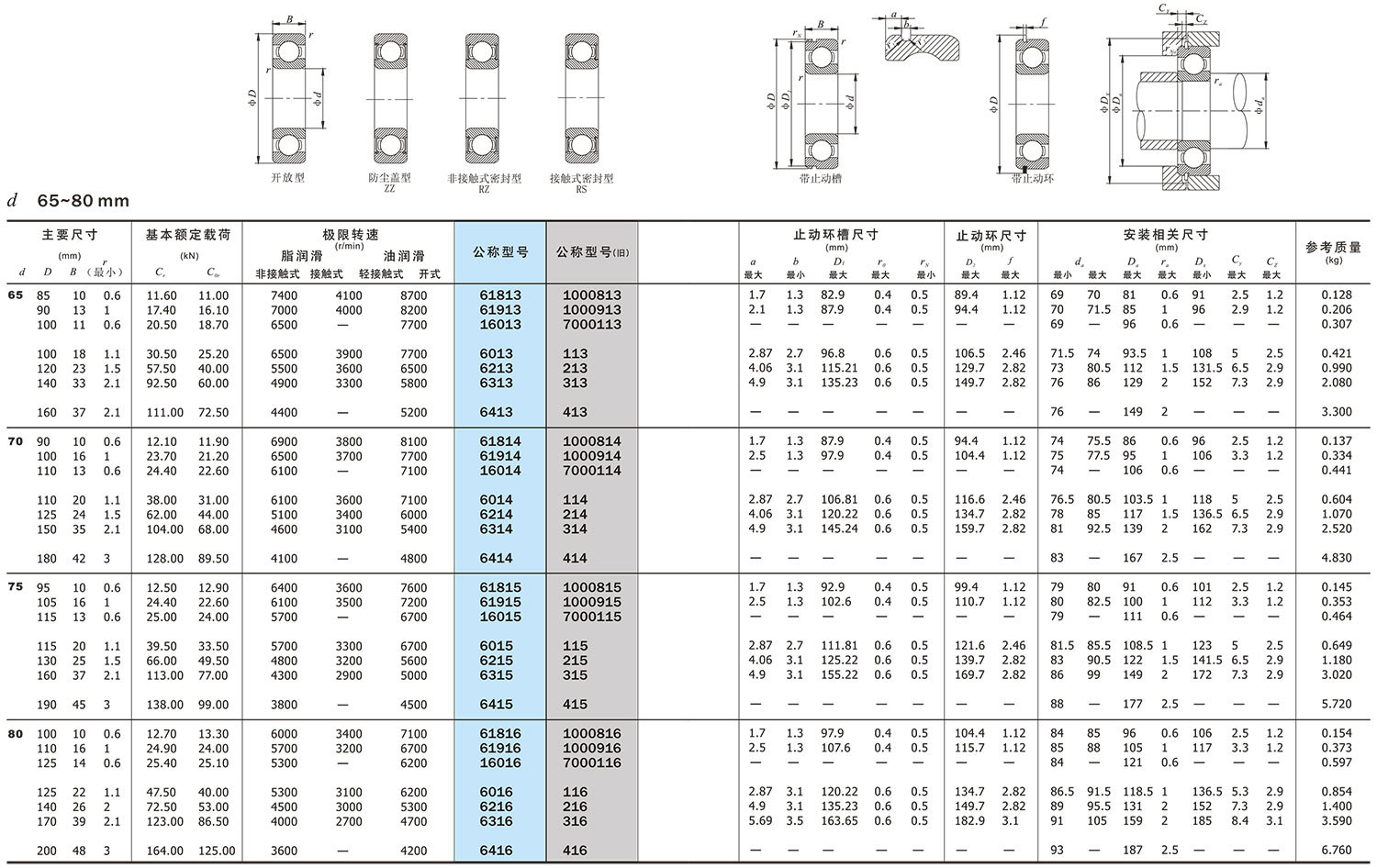

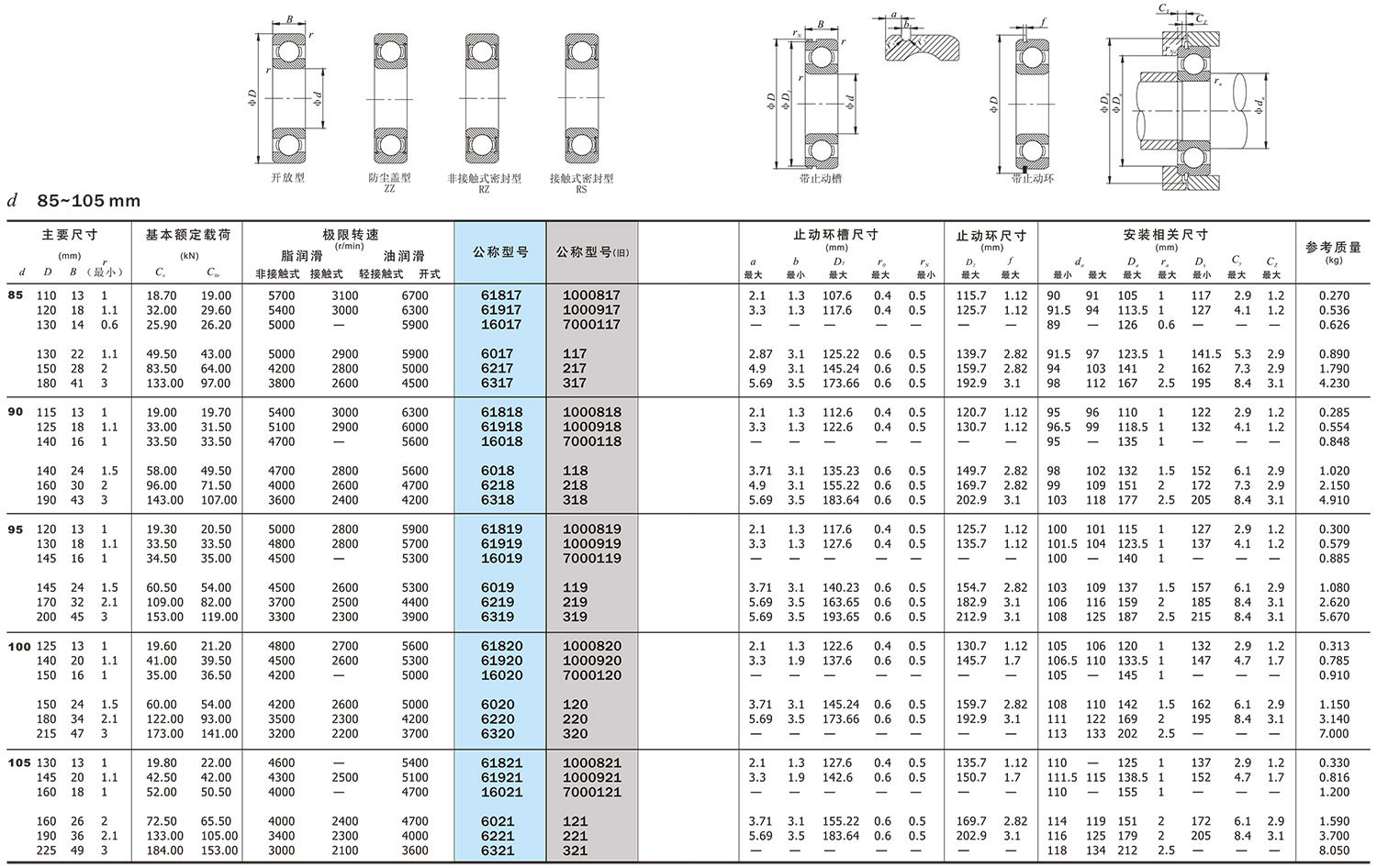

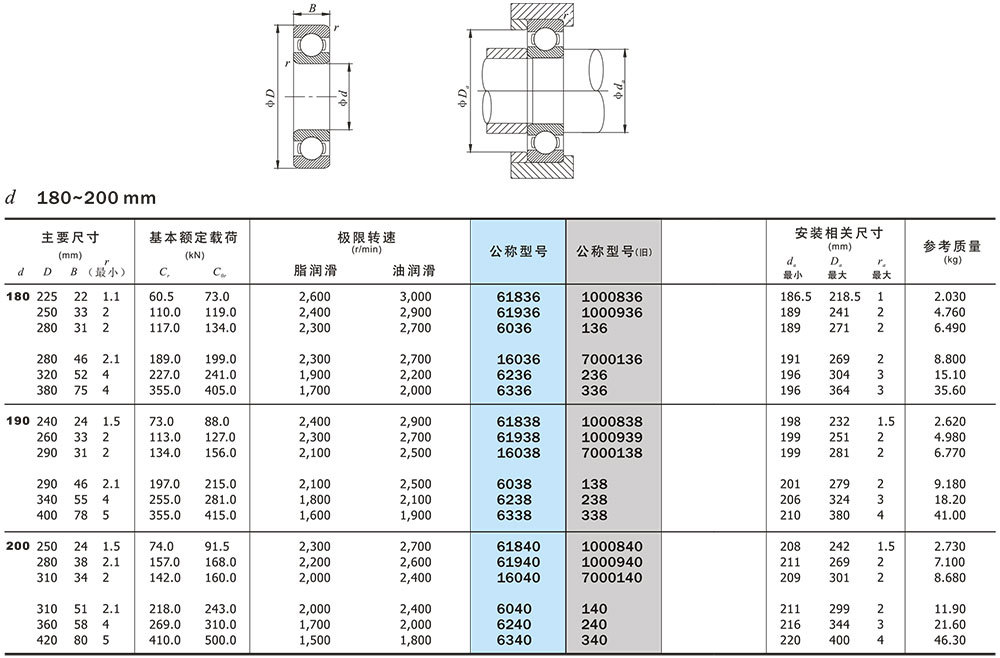

Product Details

1. Brief introduction

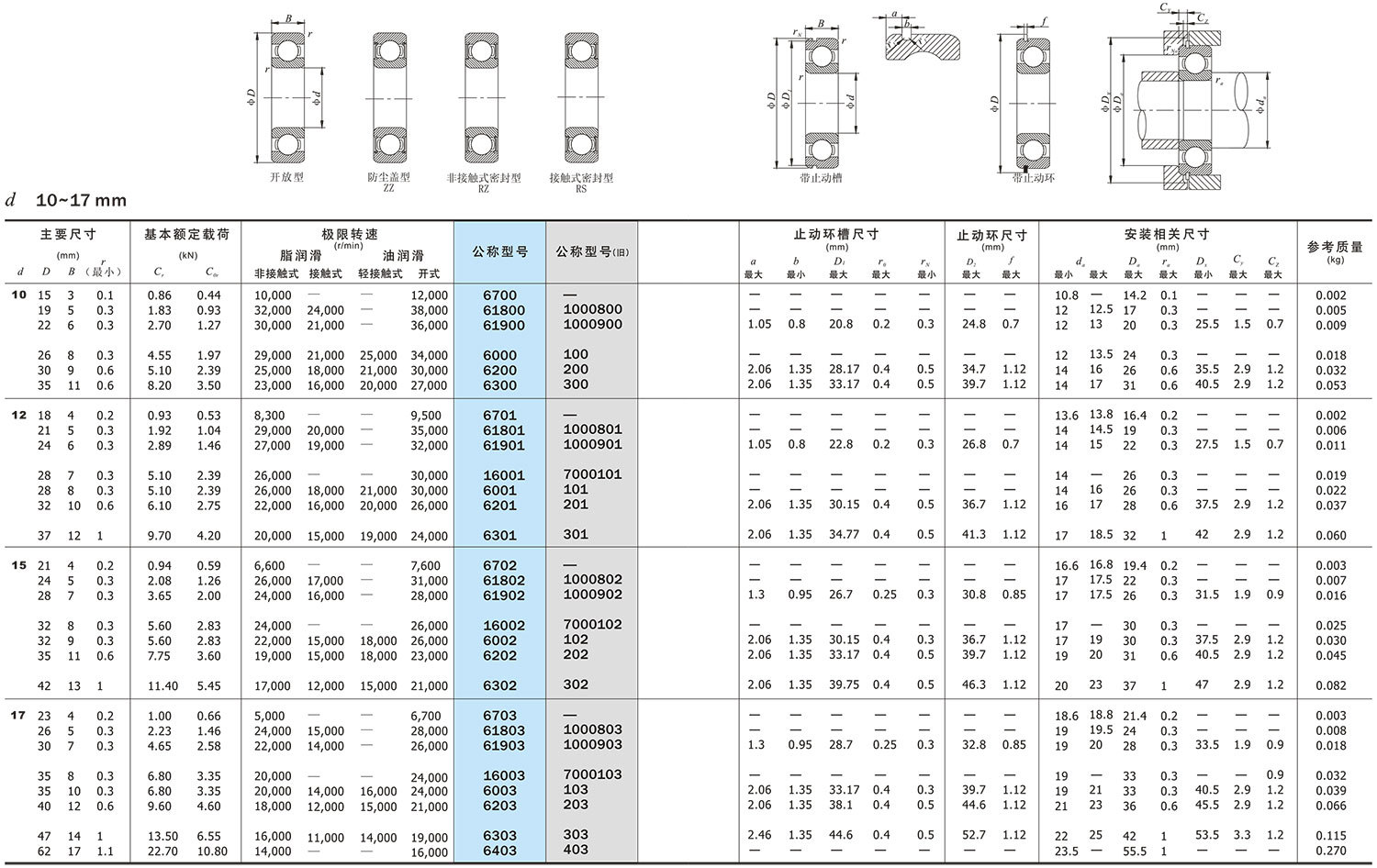

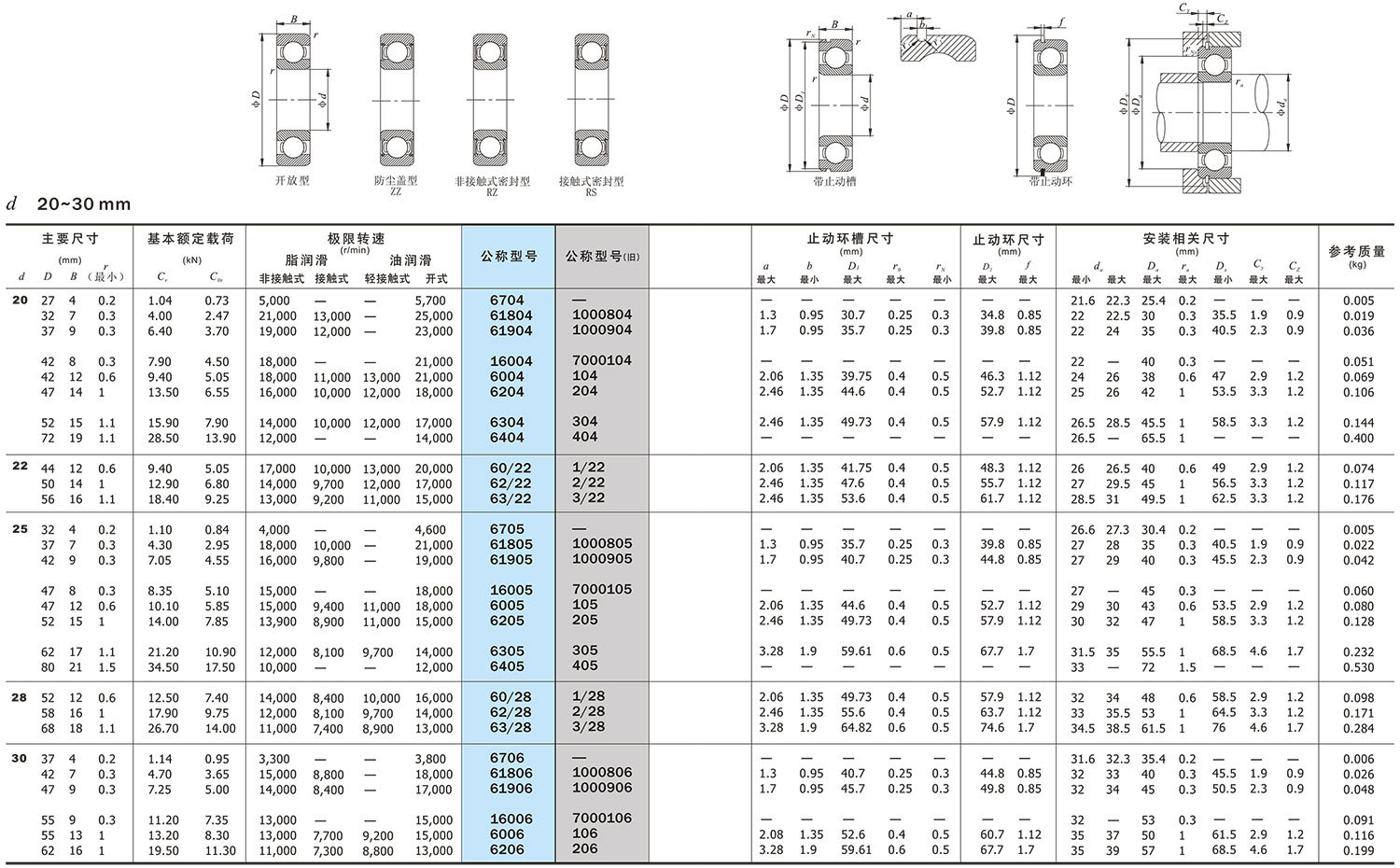

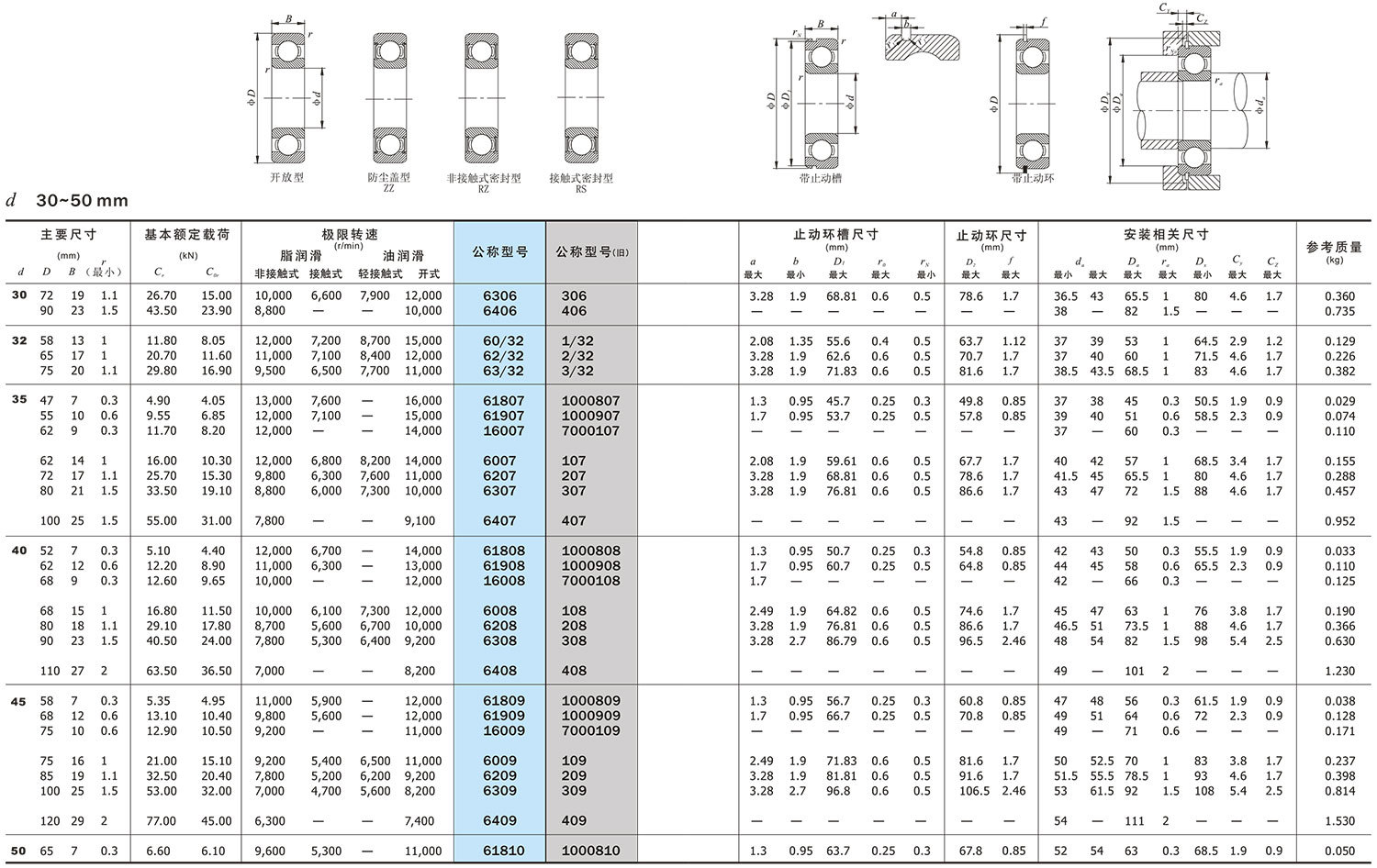

Deep groove ball bearing is the most common type of rolling bearing, and its inner and outer raceways are arc-shaped deep grooves.

Deep groove ball bearings are mainly used to bear radial loads and small axial loads. The friction coefficient of deep groove ball bearings is very small, and the limit speed is also high. Its sealed structure products do not need relubrication and maintenance.

The structure of the deep groove ball bearing is simple, and it is easy to achieve higher manufacturing precision compared with other types. It can be produced in large quantities, the manufacturing cost is also low, and it is extremely convenient to use.

In addition to the basic type, deep groove ball bearings also have various variant structures, such as (see the example on the right for details):

Deep groove ball bearing with dust cover; deep groove ball bearing with rubber sealing ring; deep groove ball bearing with stop groove; deep groove ball bearing with filling port; double row deep groove ball bearing.

|

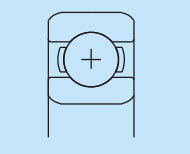

Open base structure |

|

The most commonly used basic structure is represented by the basic code, for example: 6204 |

|

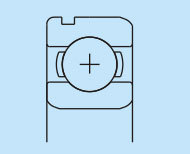

Bearing structure with stop groove |

|

Use "N" after the model, for example: 6204N |

|

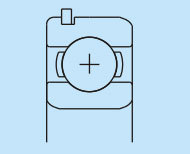

Bearing structure with snap ring |

|

Use "NR" after the model, for example: 6208NR |

|

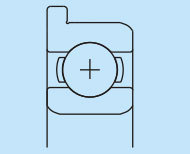

With flanged bearing structure |

|

Commonly used miniature bearings, add "F" before the code, for example: F683 |

|

Dust cover sealing structure |

|

Use "Z" after the code to indicate "Z" on one side and "2Z" on both sides, for example: 6204-Z, 6204-2Z |

|

Non-contact sealing structure |

|

Use "RZ" after the code, "RZ" on one side and "2RZ" on both sides, for example: 6204-RZ, 6204-2RZ |

|

Contact seal structure |

|

Use "RS" after the code name, "RS" on one side and "2S" on both sides, for example: 6204-RS, 6204-2RS |

|

High Load Deep Groove Ball Bearings |

|

Non-standard products can increase the number of steel balls and improve the load capacity. Add "E" after the code, for example: 6210E |

|

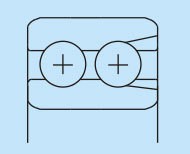

Double Row Deep Groove Ball Bearings |

|

There are often two series of 42XX and 43XX, for example: 4205, 4305 |

1) Deep groove ball bearings with shields

The function of the dust cover is to prevent the leakage of grease and the intrusion of external foreign matter, and there are single-sided and double-sided dust-proof covers.

Bearings with dust covers are used in occasions where it is difficult to lubricate alone, it is inconvenient to arrange the lubricating oil circuit and check the lubrication situation, and low friction torque and high temperature are required. The bearings have been filled with a certain amount and brand of grease before leaving the factory. The amount of grease for each set of bearings is usually 1/4 to 1/3 of the effective space of the bearing cavity, and the amount of grease injection can also be increased or decreased according to user requirements. The injected lubricating grease can usually guarantee the operation of the bearing under the working condition of -40~+120℃. If the user has higher requirements for the bearing, other special performance grease can be filled according to the situation. Bearings with dust covers can work effectively for a long time after being greased, and there is no need to add grease during use.

Bearings with dust covers are mostly used at both ends of rotors of small and medium-sized generators and motors, automobiles, tractors, air conditioners, fans, etc., as well as occasions that have special requirements for noise and vibration of bearings.

2) Deep groove ball bearings with rubber seals

Deep groove ball bearings with sealing rings have contact and non-contact seals, and single-sided and double-sided seals. Contact seals can be designed and manufactured as light contact, medium contact, and heavy contact according to different parts of use. Mode.

The performance, grease filling and use of bearings with seal rings are basically the same as those of deep groove ball bearings with shields. The difference is that the bearing with dust cover has a large gap between the dust cover and the inner ring, while the gap between the seal ring and the inner ring of the non-contact sealed ball bearing is very small, and the sealing lip of the contact seal ring bearing There is no gap with the inner ring, and the sealing effect is good, but the friction has increased.

Where low noise is required, small-sized deep groove ball bearings of series 60 and 62 are often used. Regardless of open bearings or closed bearings (bearings with dust cover or seal ring), low noise and low vibration requirements can be put forward when ordering.

3) Deep groove ball bearings with snap grooves and snap rings

The structure of the outer ring with stop groove, stop ring and flange can realize axial positioning, which simplifies the installation structure of the housing.

Deep groove ball bearings with stop grooves and stop rings are mostly used in working parts such as automobiles and tractors.

4) Deep groove ball bearings with filling notches

The main dimensions of deep groove ball bearings with filling gaps are the same as the 62 or 63 series of deep groove ball bearings. Both the inner and outer rings have ball filling gaps, so the number of steel balls is more than that of ordinary deep groove ball bearings, and the rated dynamic load is 20-35% larger.

This type of bearing is not suitable for occasions with large axial loads because it has a ball filling gap. When used in combined loads dominated by radial loads, the condition of radial equivalent dynamic load Pᵣ<0.5C₀ᵣ should be met.

5) Double row deep groove ball bearings

If necessary, please contact the technical center of Renben Group.

2. Sealing

Performance Comparison of Sealed Deep Groove Ball Bearings

|

Features |

With dust cover |

With sealing ring |

||

|

Contactless |

Contactless |

Contact |

light touch |

|

|

2Z |

2RZ |

2RS |

2RS |

|

|

Friction moment |

small |

small |

big |

smaller |

|

High speed |

better |

OK |

Restricted due to contact |

better |

|

Grease tightness |

better |

Better than ZZ type |

When the speed is low, it is better than 2RZ |

Very good |

|

Dustproof |

better |

Better than ZZ type, it can also be used in the occasion of multi-powder |

Better than ZZ type, it can also be used in the occasion of multi-powder |

Very good |

|

Waterproof |

Not so good |

Better than ZZ and worse than 2RS |

Pretty good |

OK |

|

Using temperature range |

-30~110℃ |

-30~110℃ |

-30~110℃ |

|

Note: This is the operating temperature range of standard bearings. Changing the type of grease and the material of the sealing ring can expand the operating range. Please contact the technical center of Renben Group.

3. Radial Equivalent Dynamic Load

Pᵣ=XFᵣ+YFₐ

The values of X and Y are determined by the ratio of the axial load Fₐ and the basic rated static load of the bearing. The X and Y coefficients are shown in the table below:

|

Relative axial load |

Single row bearing |

e |

|||

|

f₀Fₐ |

Fₐ |

Fₐ |

|||

|

X |

y |

X |

y |

||

|

0.172 1.03 3.45 |

1 |

0 |

0.56 |

2.3 1.55 1.15 |

0.19 0.28 0.38 |

4. Radial equivalent static load

P₀ᵣ=0.6Fᵣ+0.5Fₐ

When P₀ᵣ<Fᵣ, take P₀ᵣ=Fᵣ

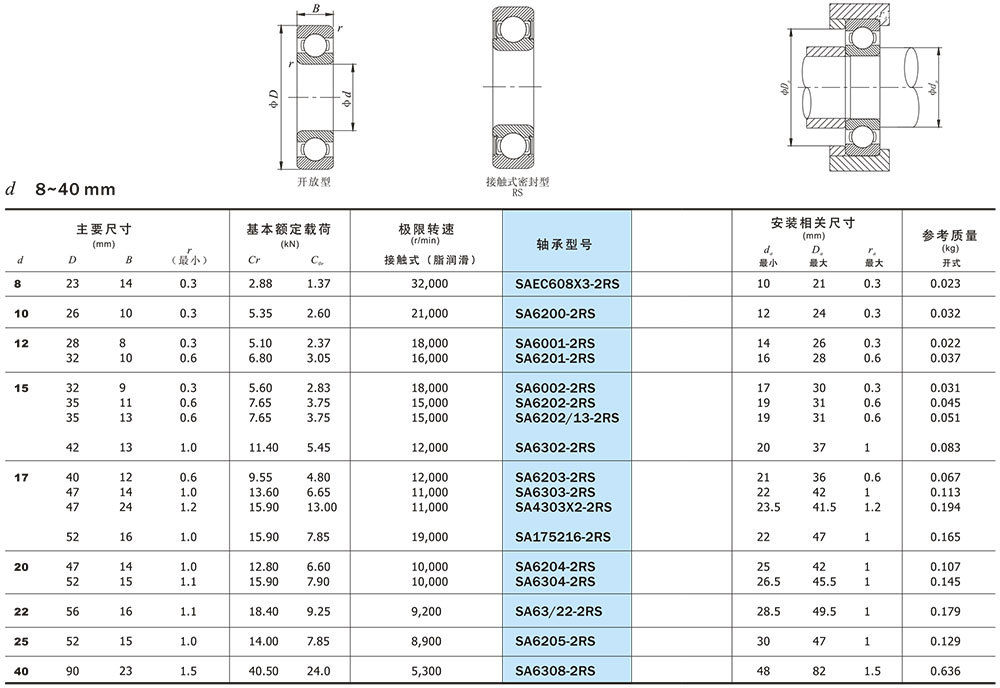

"SA" Series Automobile Alternator Bearings

Automobile alternators, long-term exposed to brush wear particles and external dust and muddy water, operate from low speed to high speed under high temperature and high load, and their working conditions are very harsh, so the requirements for their bearings are very high . These requirements are mainly: high reliability, high fatigue life, high sealing performance, and high temperature resistance.

C&U automotive alternator bearings are designed according to their actual working conditions, using special raw materials, heat treatment methods, sealing structures, lubrication schemes, etc., which perfectly meet the needs of working conditions. These products are distinguished by adding "SA" before the code .

"TM" series deep groove ball bearings for automotive gearboxes

Deep groove ball bearings for automobile gearboxes work in the oil mist environment formed by the lubricating oil in the gearbox, and metal impurities such as gear wear iron chips contained in the lubricating oil will enter the inside of the bearing, which will easily cause the outer starting point of the raceway to peel off At the same time, because the gearbox mainly transmits torque by helical gears, helical gears and other forms of gears, the bearings must be able to withstand large axial loads and impact loads. With the advancement of technology, people are concerned about reliability, vibration and noise put forward higher requirements.

C&U deep groove ball bearings for automotive gearboxes adopt the design method of ultimate load according to their actual working conditions, and at the same time use special raw materials, heat treatment methods, sealing structures, etc., which perfectly meet the needs of working conditions. This type of product is code-named Add "TM" before to distinguish.

Single Row Deep Groove Ball Bearings

"SA" Series Automobile Alternator Bearings

"TM" series deep groove ball bearings for automotive gearboxes

Type

Inside Diameter(mm)

Outside Diameter(mm)

Breadth(mm)

Weight(g)

Dynamic Load(N)

Static Load(N)

Supply From Stock

-

-

-

-

-

-

-

-

Factory

Previous Article

Next Article

Previous Article

Next Article

FAQ

Q

Are you a manufacturer?

A

Yes, we are a strong manufacturer.

Q

Can we visit your factory?

A

Of course, welcome to our factory for on-site inspection.

Q

Can we order samples?

A

Yes, we support customization.

Q

Can you arrange shipment? What are the physical methods?

A

Yes Can be arranged by sea shipping.

Q

What is your lead time?

A

Within 30 days after we confirm your request .

Q

What payment methods do you support?

A

T/T, 100% L/C at sight, Cash, Western Union are all accepted if you have other payment,please contact me.

Get a Free Quote

Series of Products