Angular Contact Ball Bearings

Payment Terms:

T/T

100% L/C

Cash

Western Union

Delivery Time:

30 Days

Keywords:

Series:

Product Details

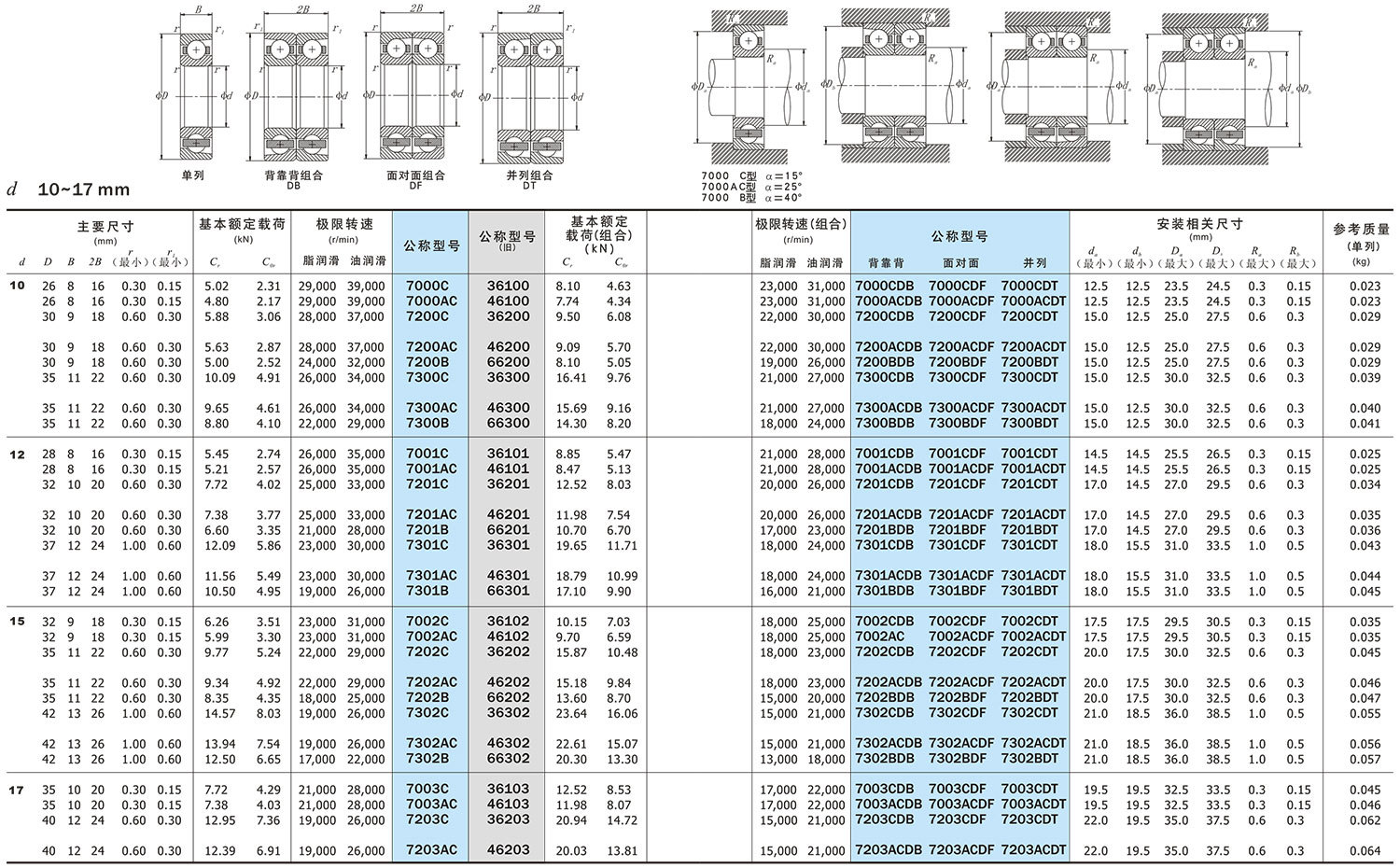

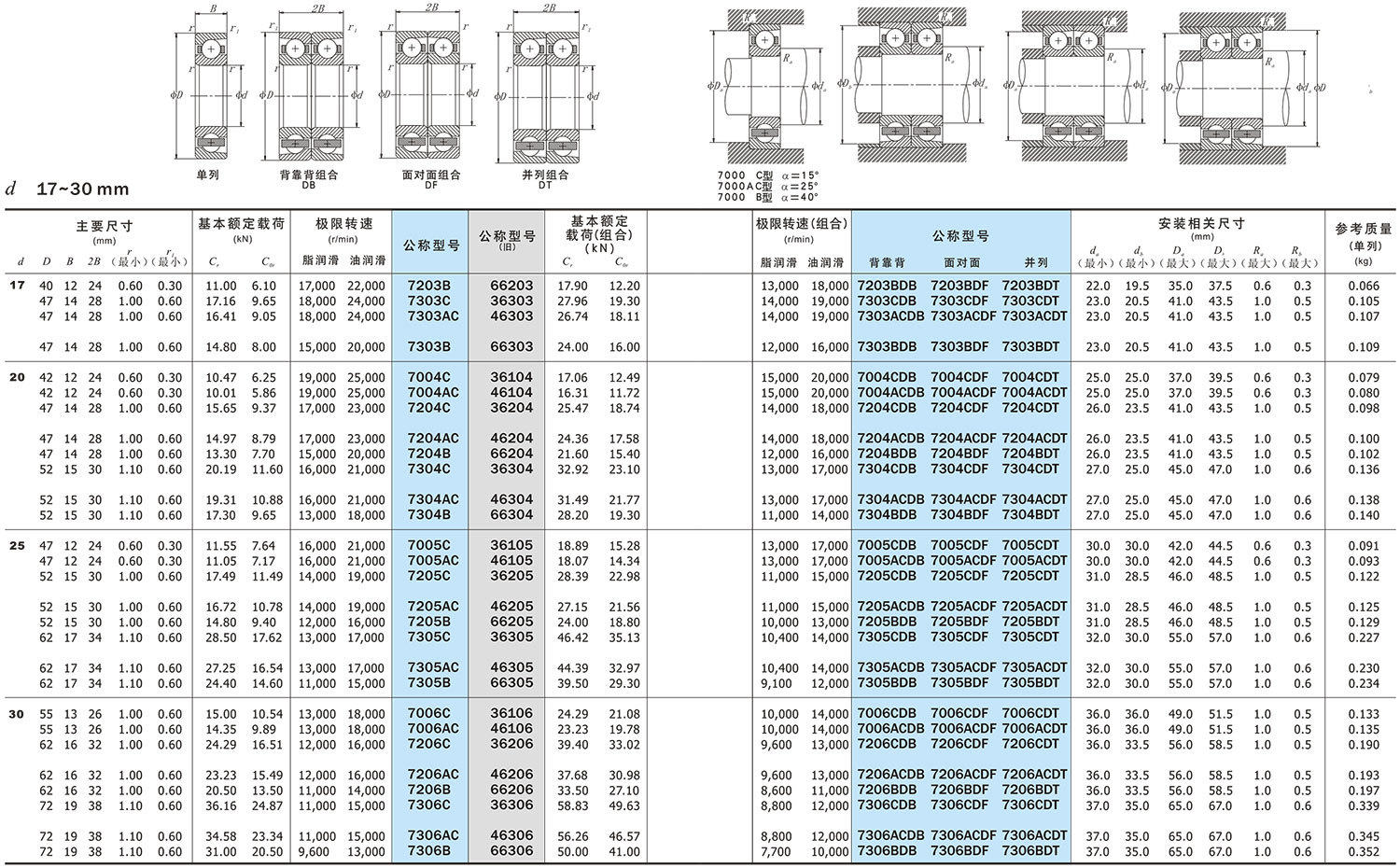

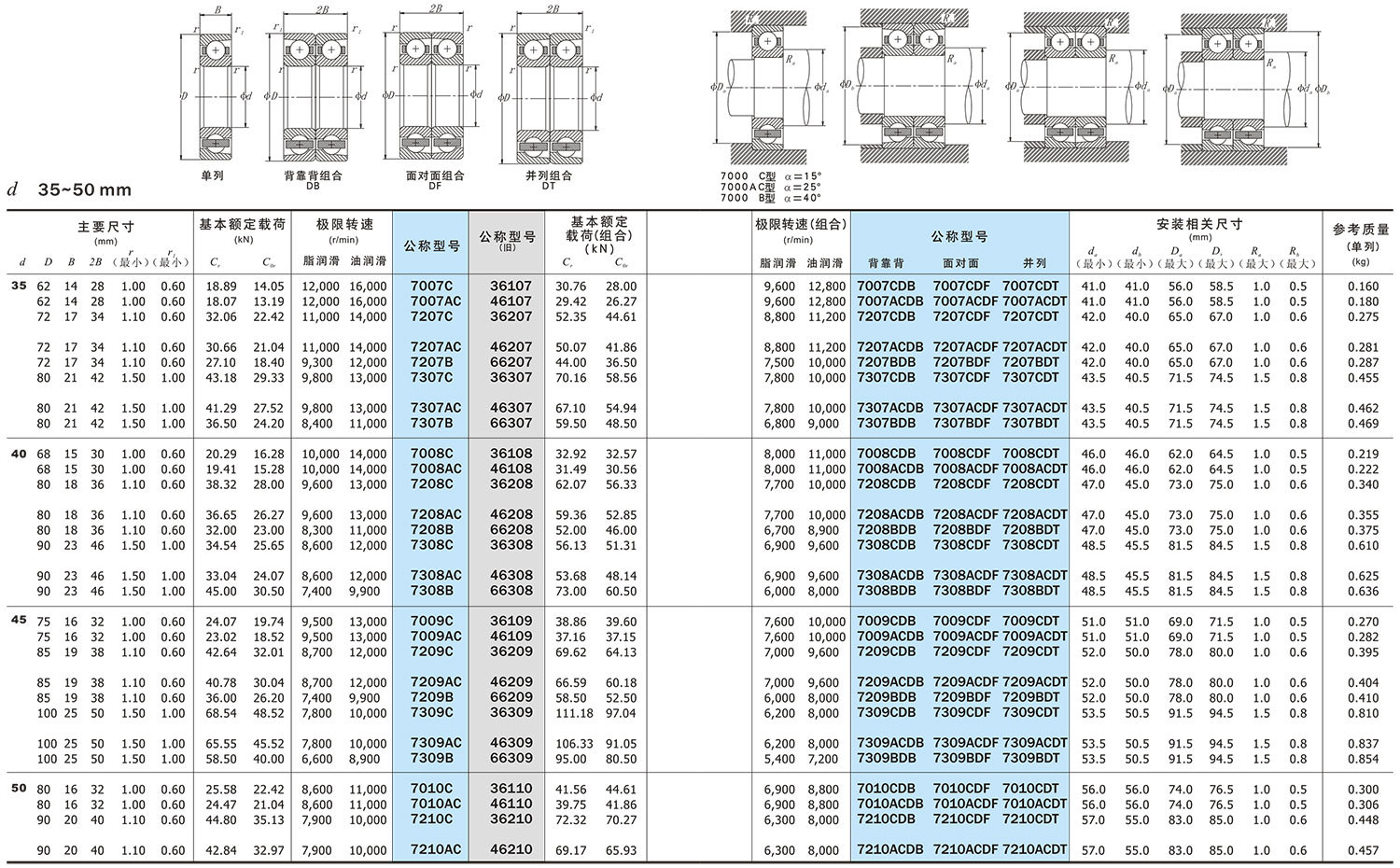

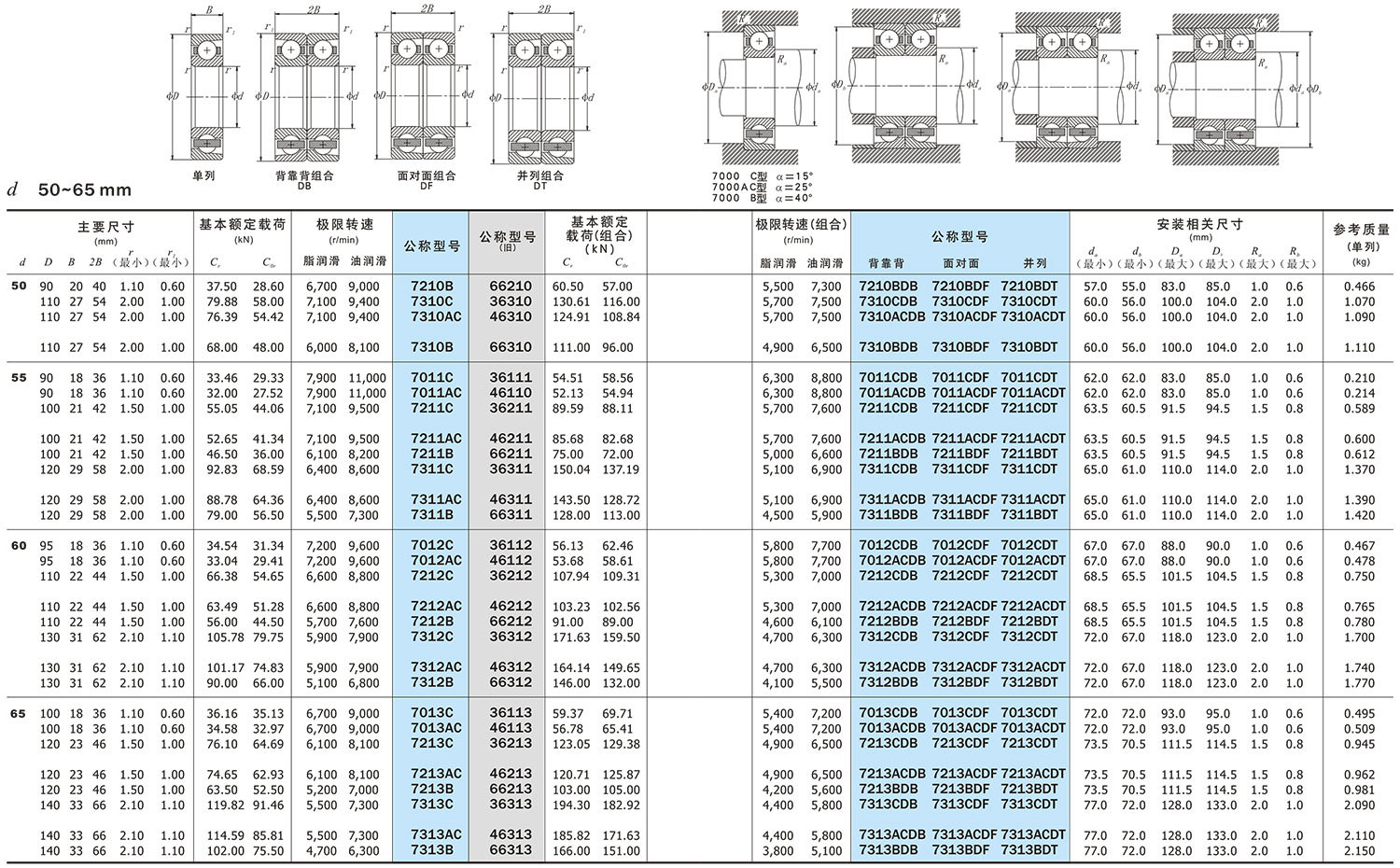

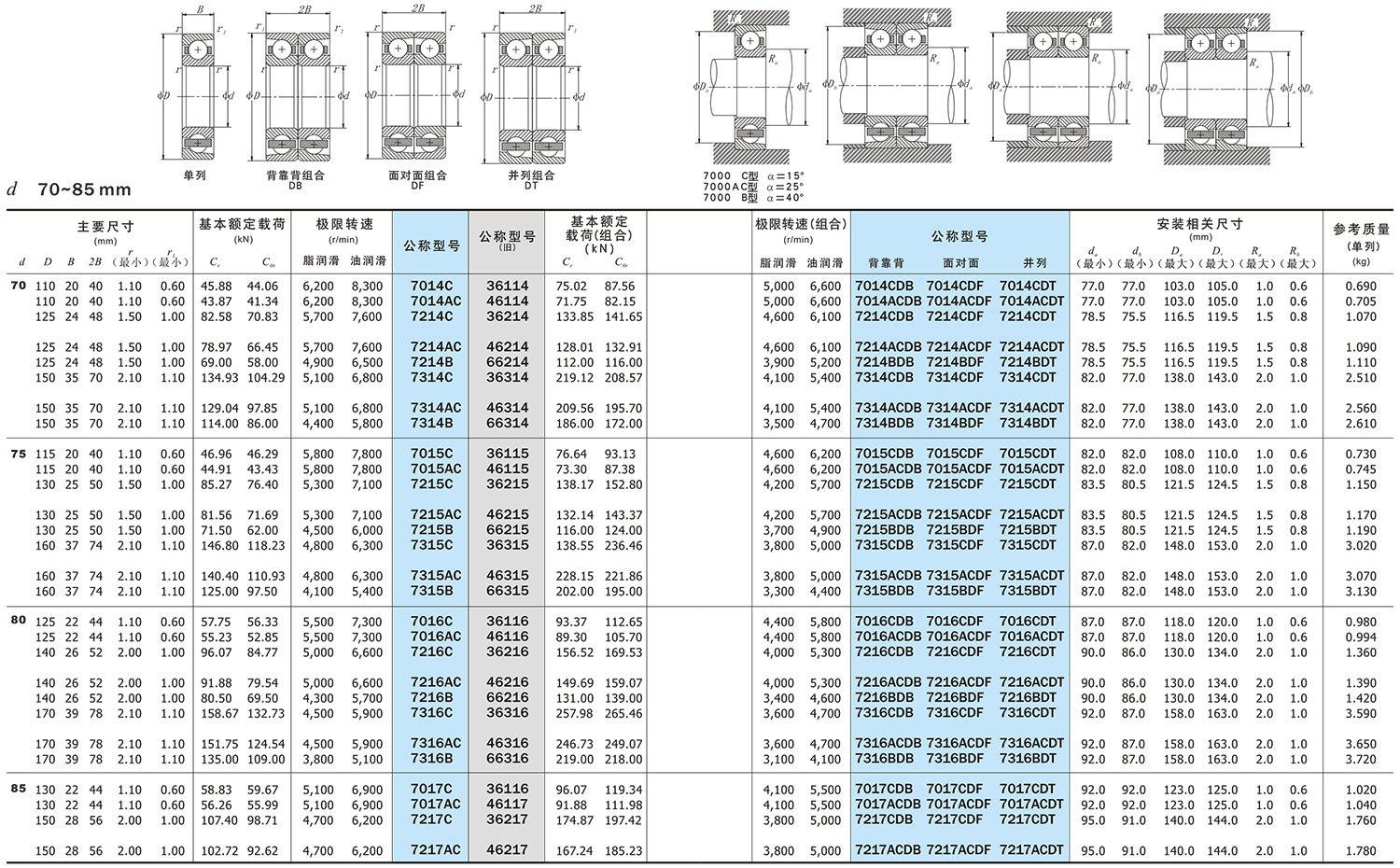

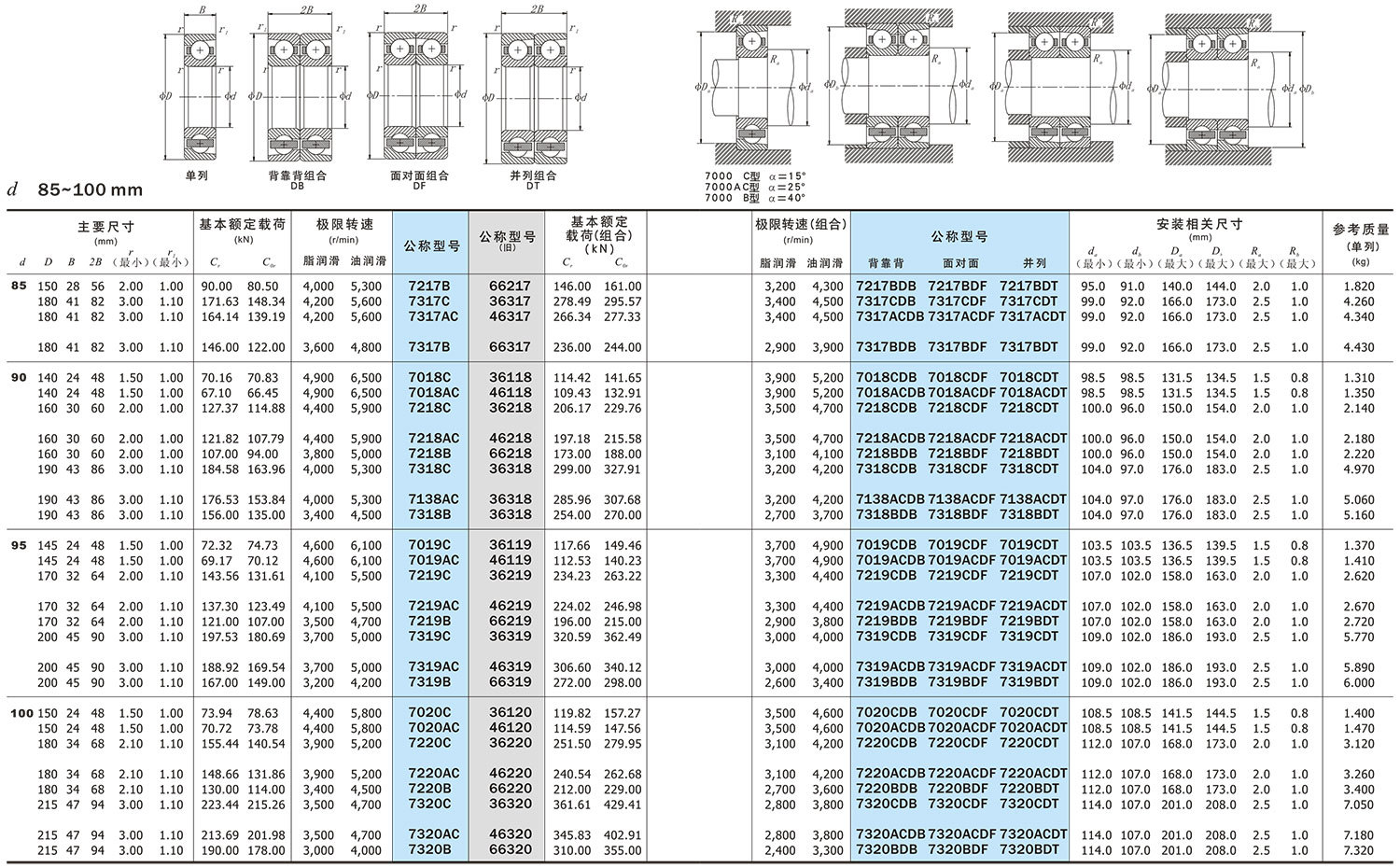

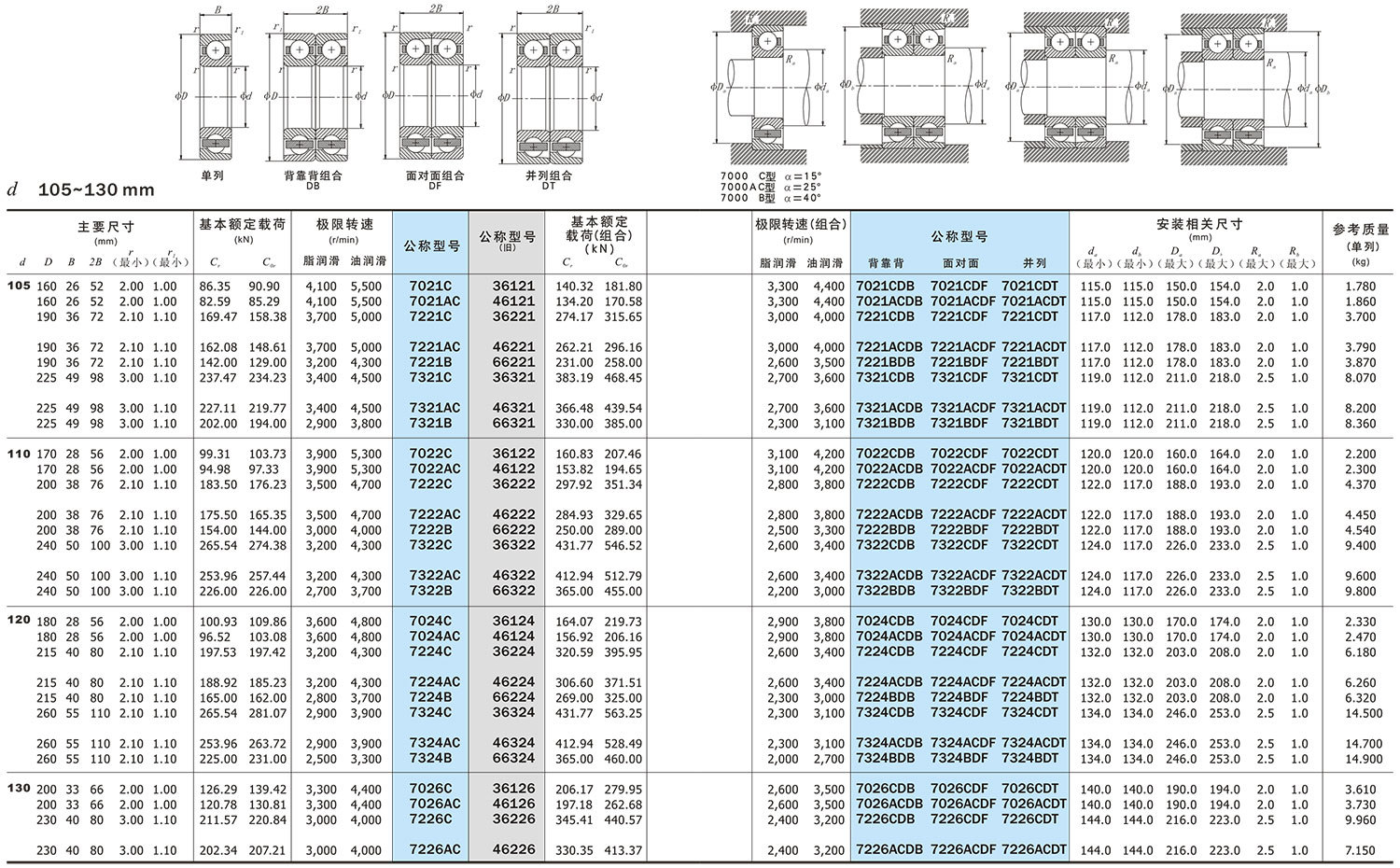

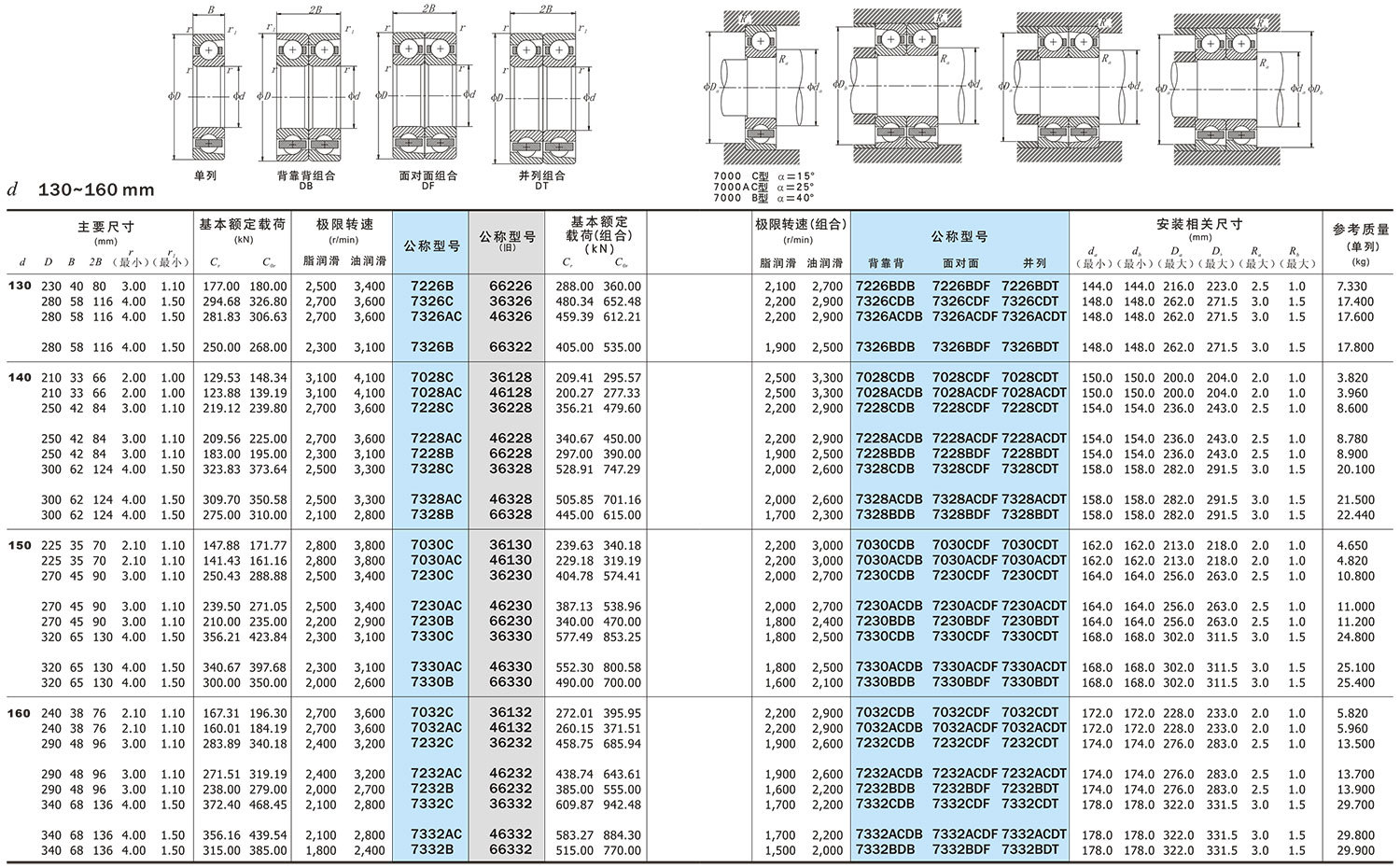

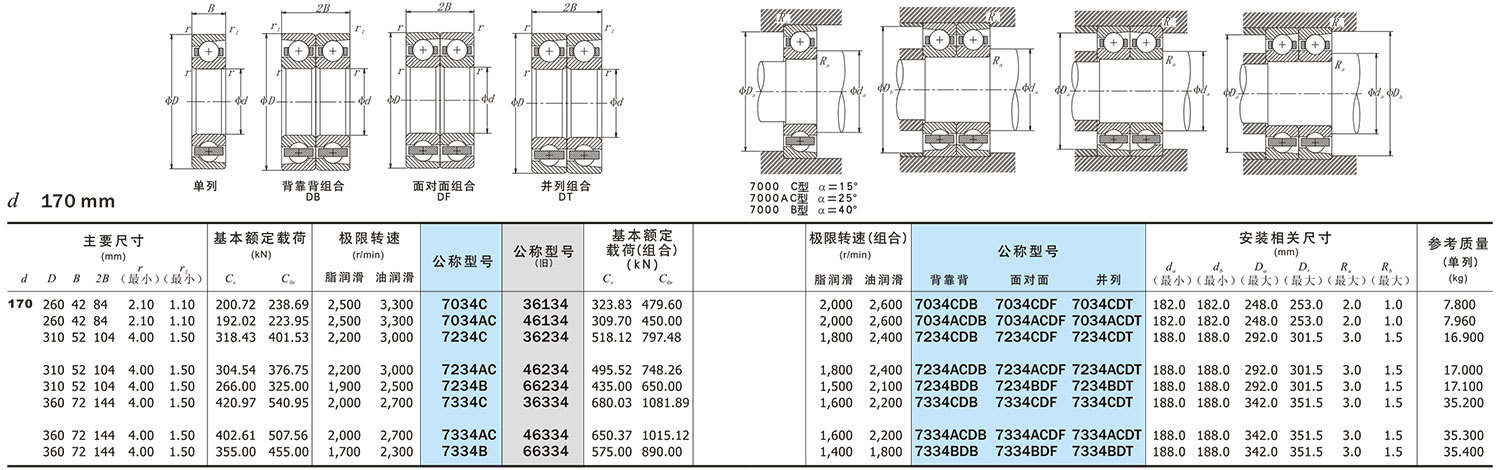

1. Single row angular contact ball bearings

These bearings have contact angles and are therefore suitable for axial loads in one direction, or combined loads.

Structurally, axial component force will be produced after bearing radial load, so two bearings should be used in pairs, or more than two bearings should be used in pairs. Single row angular contact ball bearings can be preloaded to increase rigidity, so they are suitable for machine tool spindles with high rotational accuracy, etc.

The contact angles of standard products are 15° (code C), 25° (code AC) and 40° (code B), and the bearing cages with contact angles of 15° and 25° are mostly made of bakelite. The bearing cage materials with 40° contact angle include copper, nylon, steel plate and so on.

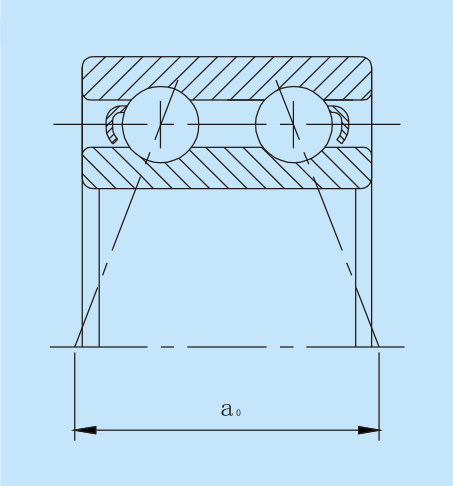

2. Pairs of double angular contact ball bearings

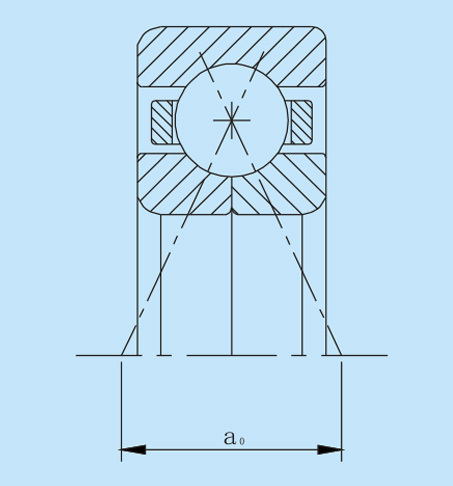

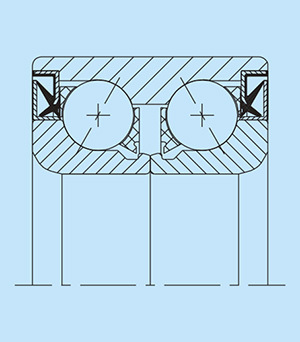

The structure and characteristics of the paired double angular contact bearings are shown in Table 1.

Table 1 Structural features of pairs of double angular contact bearings

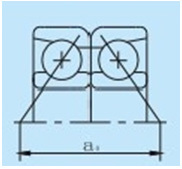

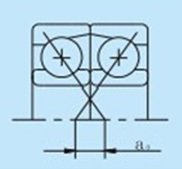

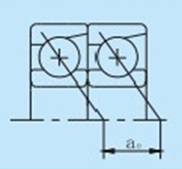

Legend | Structure | Feature |

| back-to-back double | Can withstand radial loads and axial loads in both directions. |

|

face-to-face double | Can withstand radial loads and axial loads in both directions. |

| side-by-side duplex | Can bear radial load and axial load in one direction. The axial load is supported by two bearings, so it is used in occasions where the load in one direction is large. |

Note: The value of the action point a0 is not given in the size table, please contact the technical center of Renben Group if necessary.

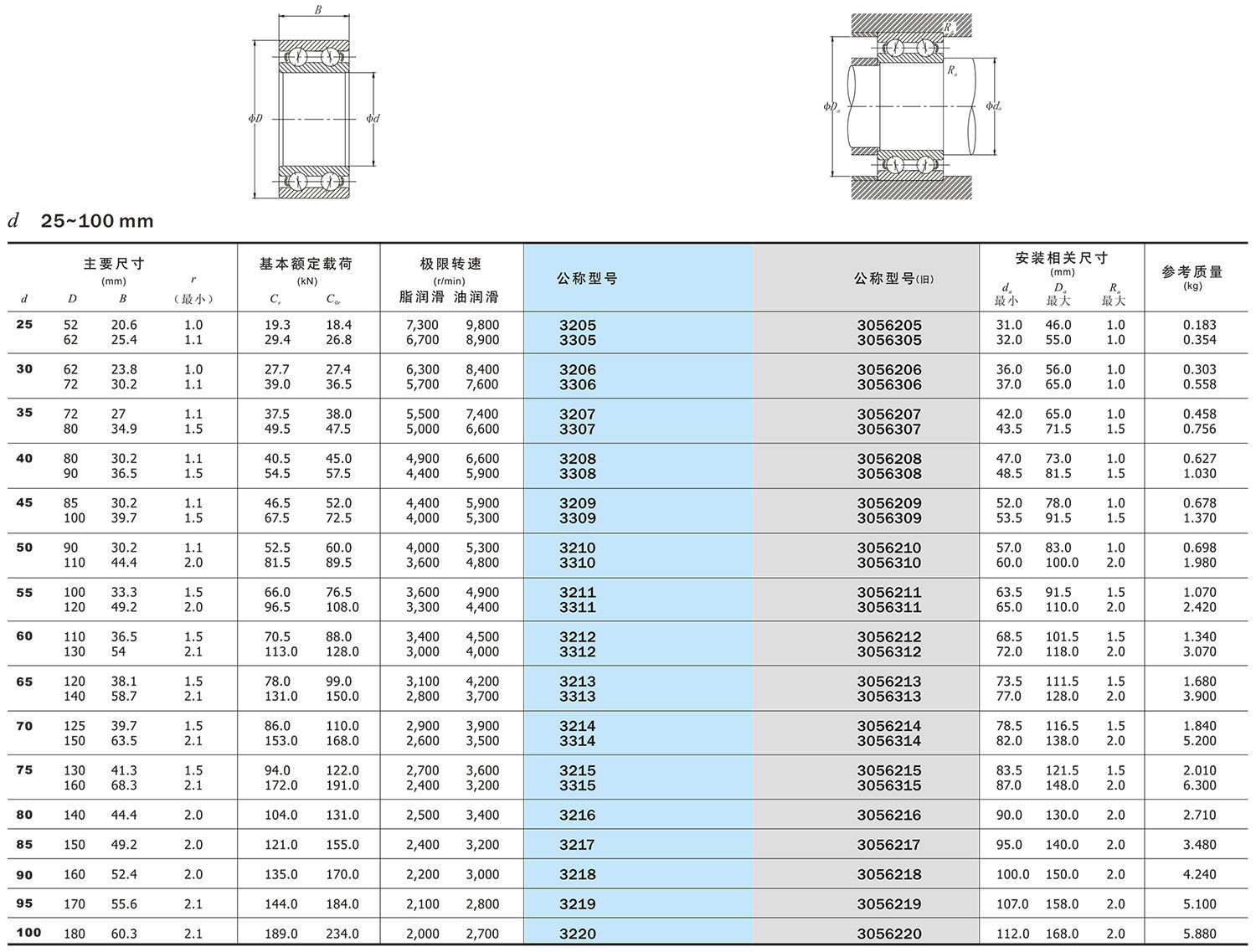

3. Double row angular contact ball bearings

The inner and outer rings of the back-to-back duplex bearing are made into an integrated structure, which can bear axial loads in two directions, and has a large moment load capacity. It can be used as a fixed end bearing.

Stamped cages or nylon cages are often used.

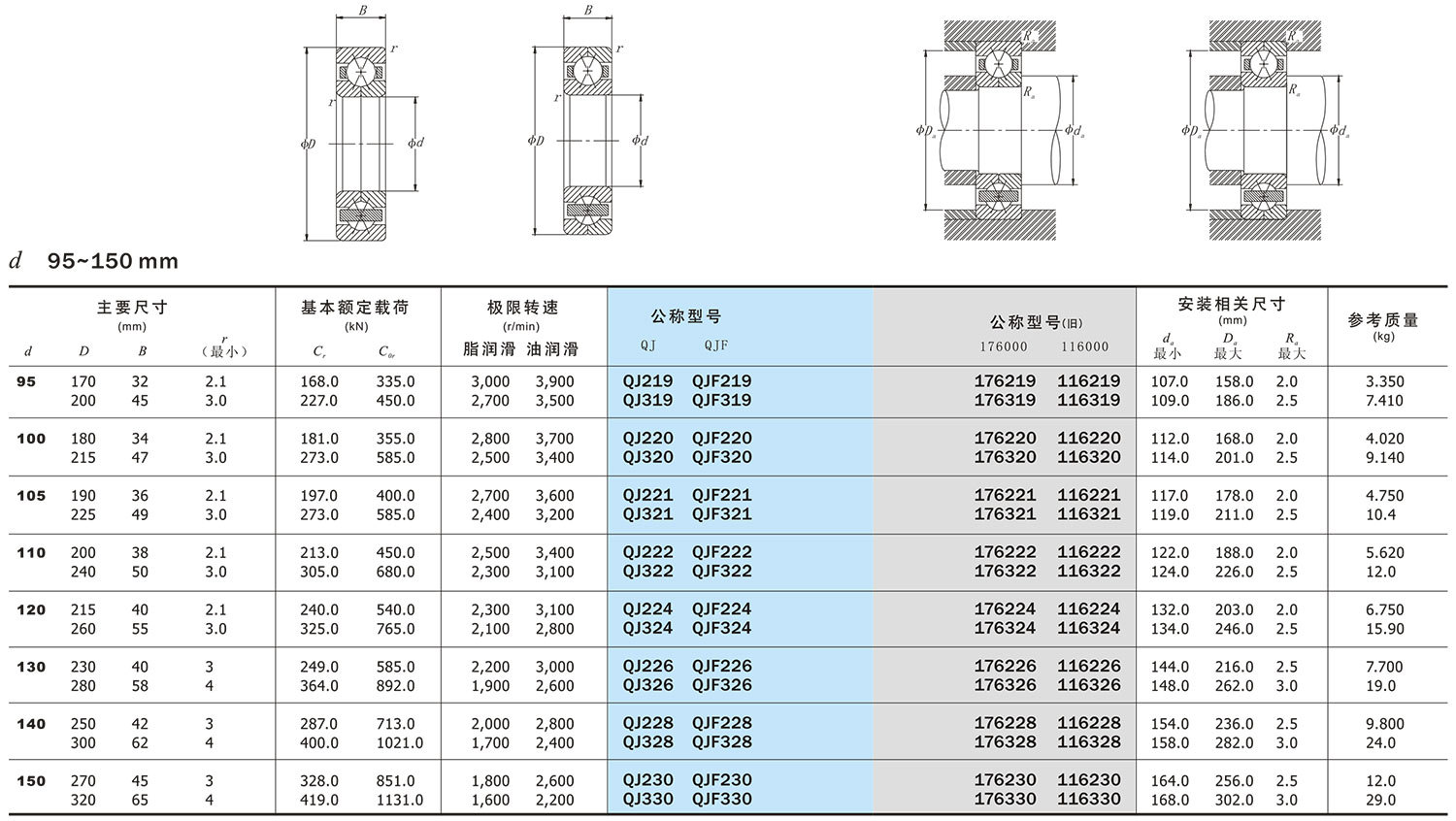

4. Four-point contact ball bearings

The inner ring is divided into two, so that one bearing can bear axial loads in two directions.

The contact angle is 35°, and the axial load capacity is large, which is suitable for bearing pure axial load or synthetic load with large axial load.

Copper alloy car cages are often used.

5. Magnetic clutch bearings for automotive air-conditioning compressors

The electromagnetic clutch bearings of automobile air-conditioning compressors are special products, which are designed under the conditions of installation dimensions and working conditions provided by customers. Its structure is similar to that of double-row radial thrust ball bearings, but double-row ball bearings for air conditioner electromagnetic clutches have the following advantages:

High temperature resistance, high speed and high reliability: Since the air conditioner electromagnetic clutch double row ball bearing is installed near the engine, it works under high temperature for a long time. C&U bearings use a special heat treatment process and select high-performance grease to meet high temperature performance.

Good sealing performance: Due to the harsh working environment, it has been working for a long time in an environment of dust and water vapor. By adopting a unique sealing structure, it can fully meet the working requirements of this environment.

This type of product has high precision and low noise performance, and can mass produce products of all sizes and specifications.

6. The first generation of car wheel bearings

The first generation of car wheel bearings is a special product, which is designed under the conditions of installation dimensions and working conditions provided by customers. Its characteristics are as follows:

Hub bearings and their units are all made of high-quality steel, lubricating grease with excellent performance, and have the characteristics of large rated load, impact resistance, good mud and water resistance, compact structure and light weight.

Can withstand large axial and radial loads at the same time.

There is no need to add lubricant during installation, which can ensure the long-term operation of the bearing.

7. Precautions for the use of angular contact ball bearings

Depending on the type of cage, some bearings may not be suitable for use close to the limit speed and temperature of the bearing, or under the harsh operating conditions of less lubricating oil, large vibration and moment load. In this case, please contact the technical center of Renben Group in advance.

In addition, during the operation of angular contact ball bearings, if the bearing load is too small, the axial and radial load ratio of the paired double bearings exceeds the value of e (recorded in the bearing size table), and sliding occurs between the ball and the raceway , causing abrasions.

Especially large angular contact ball bearings with heavy balls and cages have this tendency. Foreseeing such loading conditions in advance, please contact the technical center of Renben Group when selecting bearings.

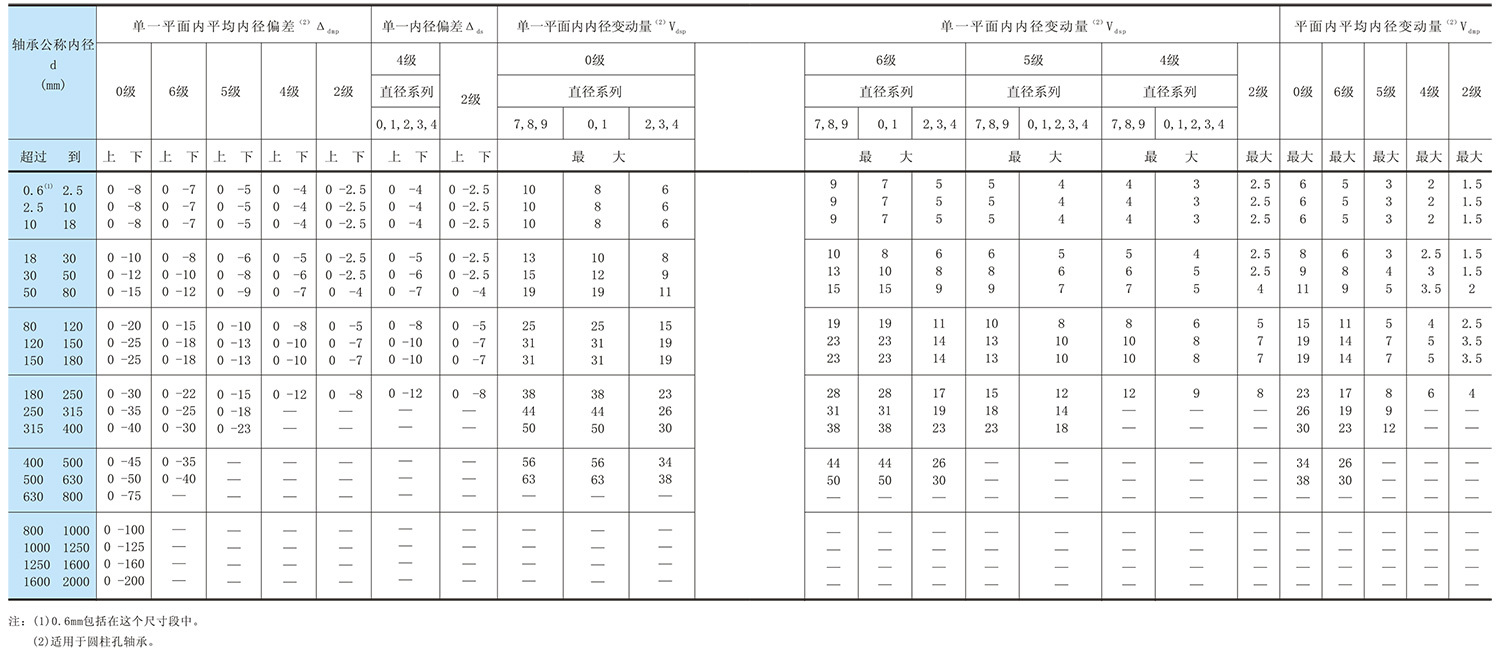

8. Dimensional Accuracy • Rotational Accuracy

Table 5.3 Tolerances of radial bearings (except tapered roller bearings)

9. Recommended cooperation

Coordination of radial bearing and shaft

Condition | Application example (reference) | Bearing nominal inner diameter d(mm) |

Shaft tolerance zone |

Remarks | |||

Ball bearing | Cylindrical roller bearing | Automatic spherical roller bearing | |||||

Outer ring rotational load | The inner ring needs to be easy to move on the shaft | Wheels with stationary axles |

All sizes | g6 | When accuracy is required, use g5, h5, large bearings and require easy inner ring movement can also use f6 | ||

Easy movement on shaft without inner ring | Tensioner frame, rope pulley | h6 | |||||

Inner ring rotating load or direction indeterminate load | Light load: |

Home Appliances, Pumps, Blowers, Trucks, Precision Machinery, Machine Tools | ≤18 | — | — | js5 |

P5 grade bearings are used when precision is required, and h5 is used for precision ball bearings with an inner diameter of 18mm or less |

18~100 | ≤40 | — | js6(j6) | ||||

100~200 | 40~140 | — | k6 | ||||

— | 140~200 | — | m6 | ||||

Normal payload: |

Some medium and large electric motors, turbines, pumps, engine shafts, gear transmissions devices, woodworking machinery | ≤18 | one | — | js5 |

For single row tapered roller bearings and single row radial thrust ball bearings, k6 and m6 can be used instead of k5 and m5 | |

18~100 | ≤40 | ≤40 | k5 | ||||

100~140 | 40~100 | 40~65 | m5 | ||||

140~200 | 100~140 | 65~100 | m6 | ||||

200~280 | 140~200 | 100~140 | n6 | ||||

— | 200~400 | 140~280 | p6 | ||||

— | — | 280~500 | r6 | ||||

— | — | >500 | r7 | ||||

Heavy Payload: |

Railway, industry vehicle, tram main motor, construction machinery, pulverizer | — | 50~140 | 50~100 | n6 |

It is recommended to use a bearing with a larger than normal clearance | |

— | 140~200 | 100~140 | p6 | ||||

— | >200 | 140~200 | r6 | ||||

— | — | 200~500 | r7 | ||||

Axial load only | The location of various bearings | All sizes | js6(j6) | —- | |||

Matching of radial bearing and housing hole

condition | Application example (reference) | Shell hole tolerance zone | Movement of the outer ring | Remarks | ||

Integral shell |

Outer ring rotational load | Thin wall bearing heavy load | Car wheel (roller bearing) Crane traveling wheel | P7 |

The outer ring cannot move in the axial direction | — |

Normal payload, | Automobile wheel (ball bearing) vibrating screen | N7 | ||||

Light load or | Conveyor pulley, pulley, tensioner | M7 | ||||

Unoriented load | Large impact load | Tram host | M7 | |||

normal payload or | Pump | K7 | In principle, the outer ring cannot move in the axial direction | The outer ring does not need to move in the axial direction | ||

Integral housing hole or separate housing | normal payload or | JS7(J7) | The outer ring can move axially | The outer ring needs to move in the axial direction | ||

Inner ring rotational load | Various loads | General bearing | H7 |

The outer ring is easy to move in the axial direction | — | |

Common payload | Bearing unit | H8 | ||||

Integral shell | Shaft and inner ring are hot | Paper dryer | G7 | |||

Non-directional load | Normal load, light load, special need for precision rotation | Grinding Spindle Rear Ball Bearing High Speed Centrifugal Compressor Fixed Side Bearing | JS6(J6) | The outer ring can move in the axial direction | — | |

Grinding Spindle Rear Ball Bearing High Speed Centrifugal Compressor Fixed Side Bearing | K6 | In principle, the outer ring is fixed in the axial direction | When the load is large, an interference fit larger than K is applicable. In the case of special requirements for high precision, it is necessary to further fit with a small allowable difference according to the application | |||

Inner ring rotational load | Varying loads, especially requiring precise rotation and high rigidity | Cylindrical roller bearings for machine tool spindles | M6 or N6 | The outer ring is fixed at | ||

Requires quiet operation | Household appliances | H6 | Outer ring to the axial direction | — | ||

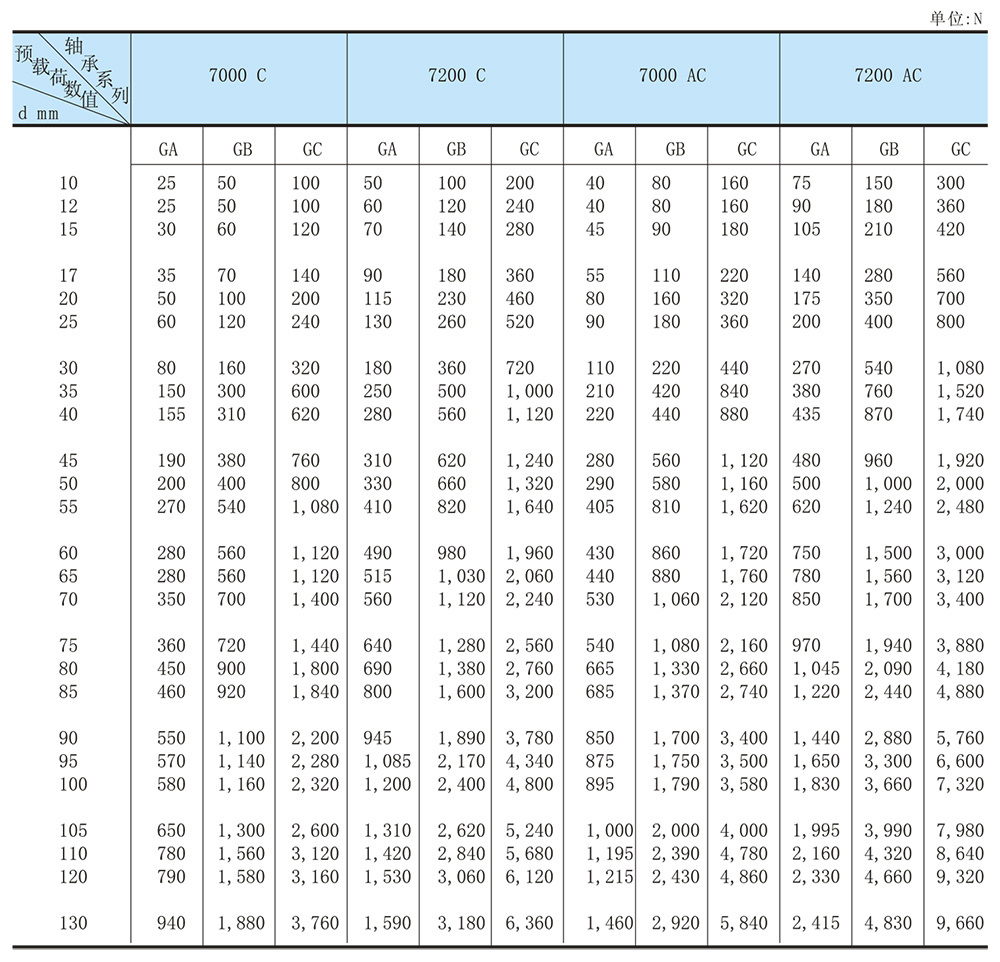

10. Clearance

High-precision paired duplex bearings above P5 are mostly used for machine tool spindles. This type of bearing is used after preloading. However, in order to facilitate the selection of slight preload, light preload, medium preload and heavy preload, the internal clearance is adjusted accordingly in advance. Moreover, the coordination is also special.

The clearance (or preload) of a pair of duplex bearings can be obtained by fastening the sides of the same inner ring or the same outer ring so that there is no gap.

For the clearance of other types of bearings, please contact the technical center of Renben Group if necessary.

Table 7.3 Preload of angular contact ball bearings mounted in pairs

11. Single row angular contact ball bearings

Equivalent static load P₀=X₀Fᵣ+Y₀Fₐ

Nominal contact angle | Single row, series combination | Back combination, front combination | ||

X₀ | Y₀ | X₀ | Y₀ | |

15° | 0.5 | 0.46 | 1 | 0.92 |

25° | 0.5 | 0.38 | 1 | 0.76 |

40° | 0.5 | 0.26 | 1 | 0.52 |

Note: When P₀>0.5Fᵣ+Y₀Fₐ in a single row or series combination, P₀=Fᵣ

Equivalent dynamic load P=XFᵣ+YFₐ

Nominal contact angle | if₀Fₐ* | e | Single row, series combination | Back combination, front combination | ||||||

Fₐ/Fᵣ≤e | Fₐ/Fᵣ>e | Fₐ/Fᵣ≤e | Fₐ/Fᵣ>e | |||||||

X | Y | X | Y | X | Y | X | Y | |||

15° | 0.178 | 0.38 | 1 | 0 | 0.44 | 1.47 | 1 | 1.65 | 0.72 | 2.39 |

25° | 一 | 0.68 | 1 | 0 | 0.41 | 0.87 | 1 | 0.92 | 0.67 | 1.41 |

40° | — | 1.14 | 1 | 0 | 0.35 | 0.57 | 1 | 0.55 | 0.57 | 0.93 |

Note: *i is i=2 in back combination and front combination, and i=1 in series combination.

12. Double row radial thrust ball bearings

Equivalent dynamic load P=XFᵣ+YFₐ

Fₐ/Fᵣ<e | Fₐ/Fᵣ>e | e | ||

X | Y | X | Y | |

1 | 0.92 | 0.67 | 1.41 | 0.68 |

Equivalent static load P=Fᵣ+0.76Fₐ

13. Four point contact ball bearing

Equivalent dynamic load Pₐ=Fₐ

Equivalent static load P₀ₐ=Fₐ

Angular Contact Ball Bearings

双列角接触球轴承

四点接触球轴承

Type

Inside Diameter(mm)

Outside Diameter(mm)

Breadth(mm)

Weight(g)

Dynamic Load(N)

Static Load(N)

Supply From Stock

-

-

-

-

-

-

-

-

Factory

Previous Article

Next Article

Previous Article

Next Article

FAQ

Q

Are you a manufacturer?

A

Yes, we are a strong manufacturer.

Q

Can we visit your factory?

A

Of course, welcome to our factory for on-site inspection.

Q

Can we order samples?

A

Yes, we support customization.

Q

Can you arrange shipment? What are the physical methods?

A

Yes Can be arranged by sea shipping.

Q

What is your lead time?

A

Within 30 days after we confirm your request .

Q

What payment methods do you support?

A

T/T, 100% L/C at sight, Cash, Western Union are all accepted if you have other payment,please contact me.

Get a Free Quote

Series of Products