Pillow Block Ball Bearing

Payment Terms:

T/T

100% L/C

Cash

Western Union

Delivery Time:

30 Days

Keywords:

Series:

Product Details

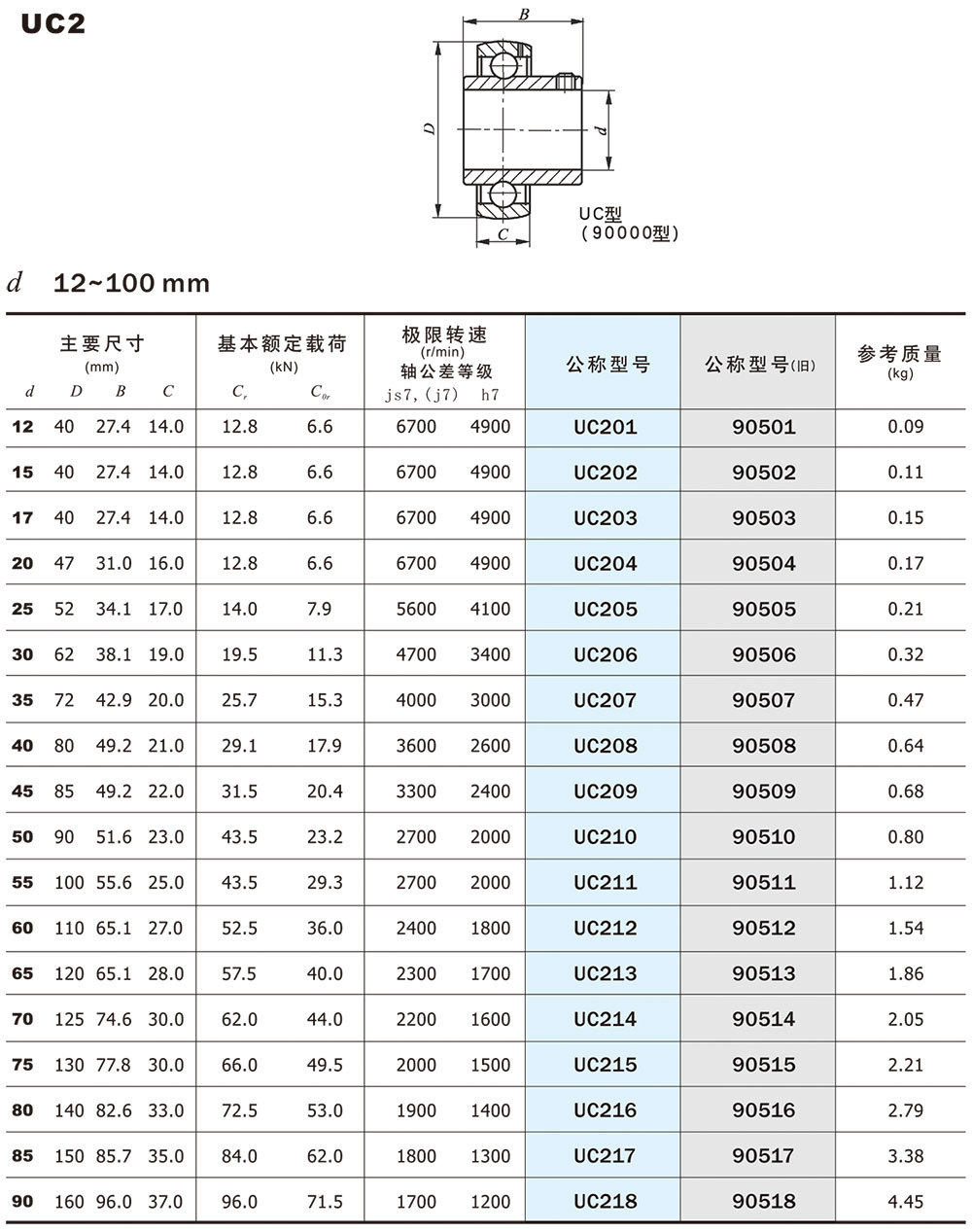

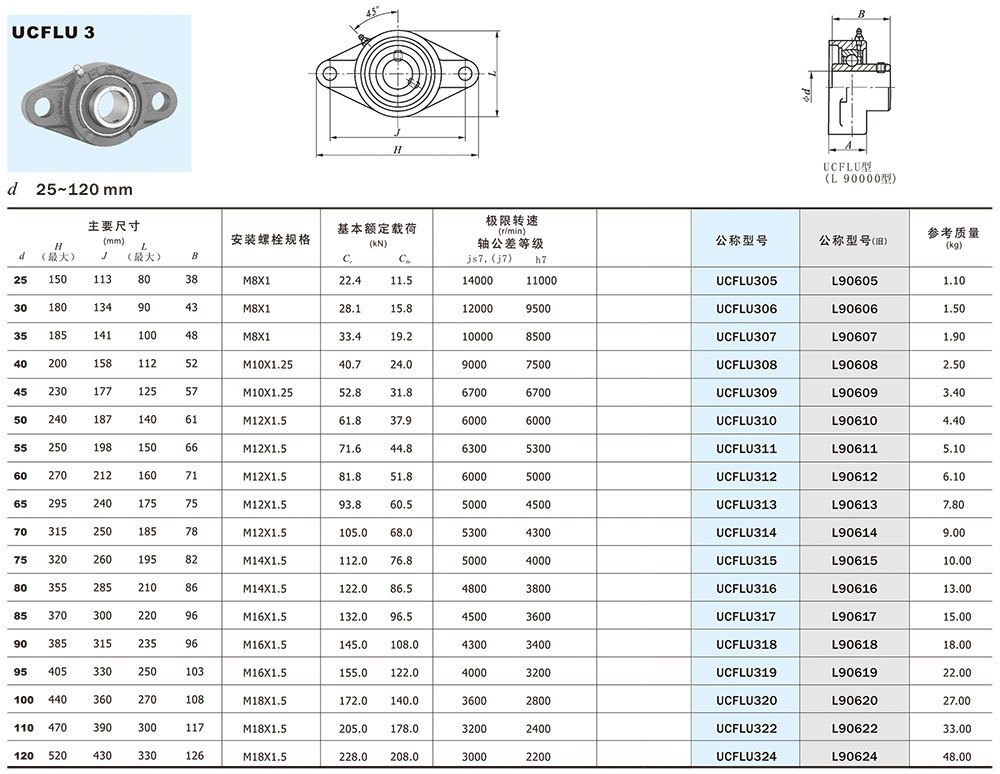

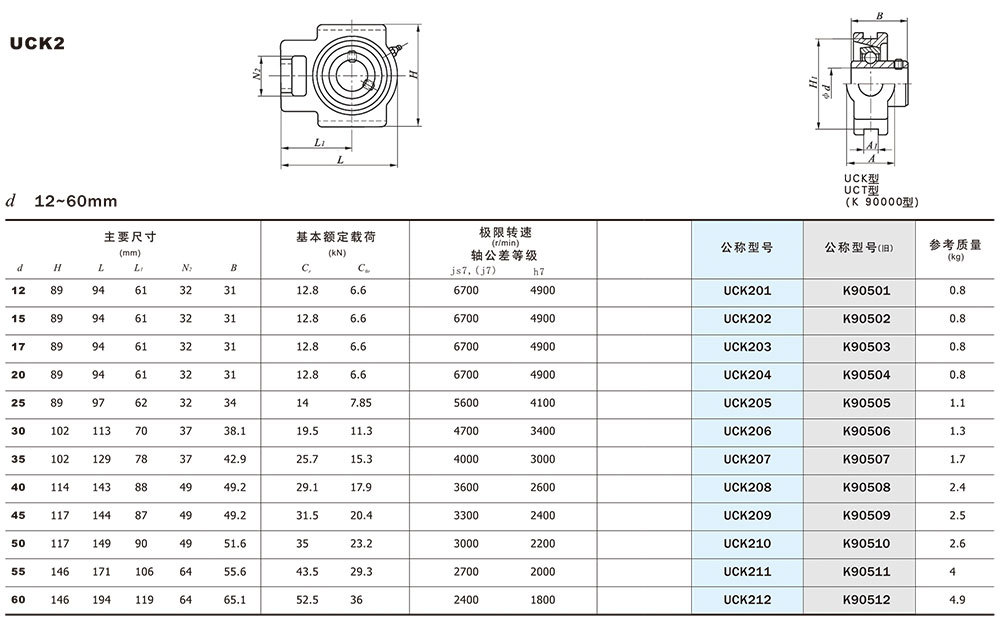

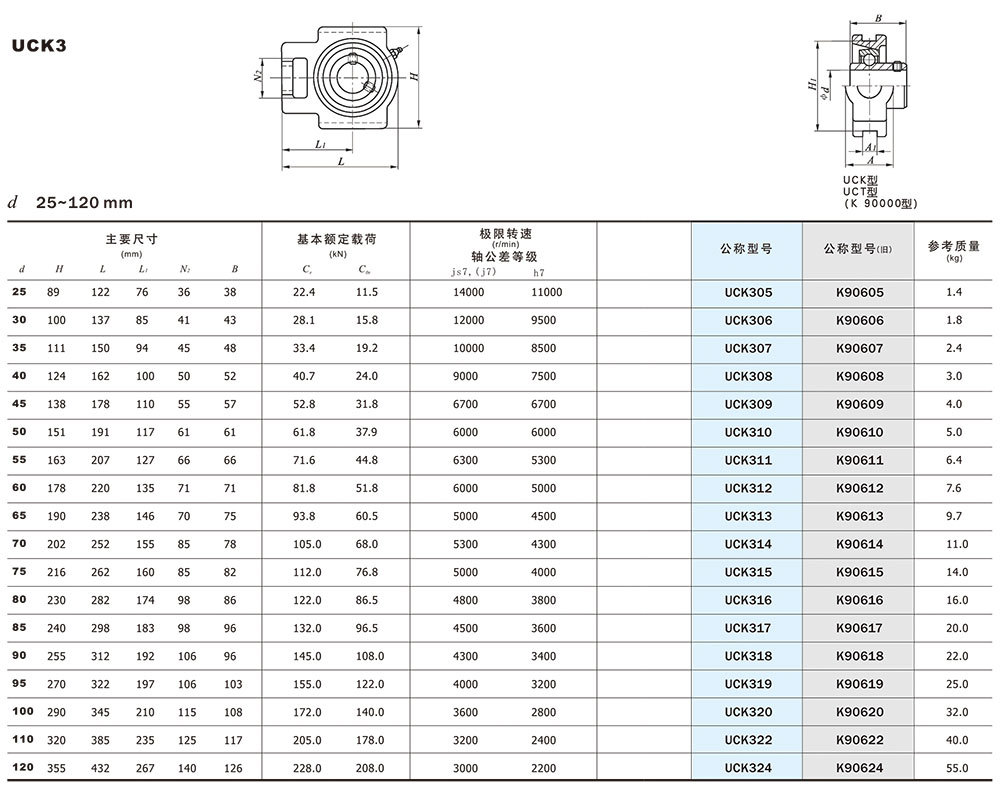

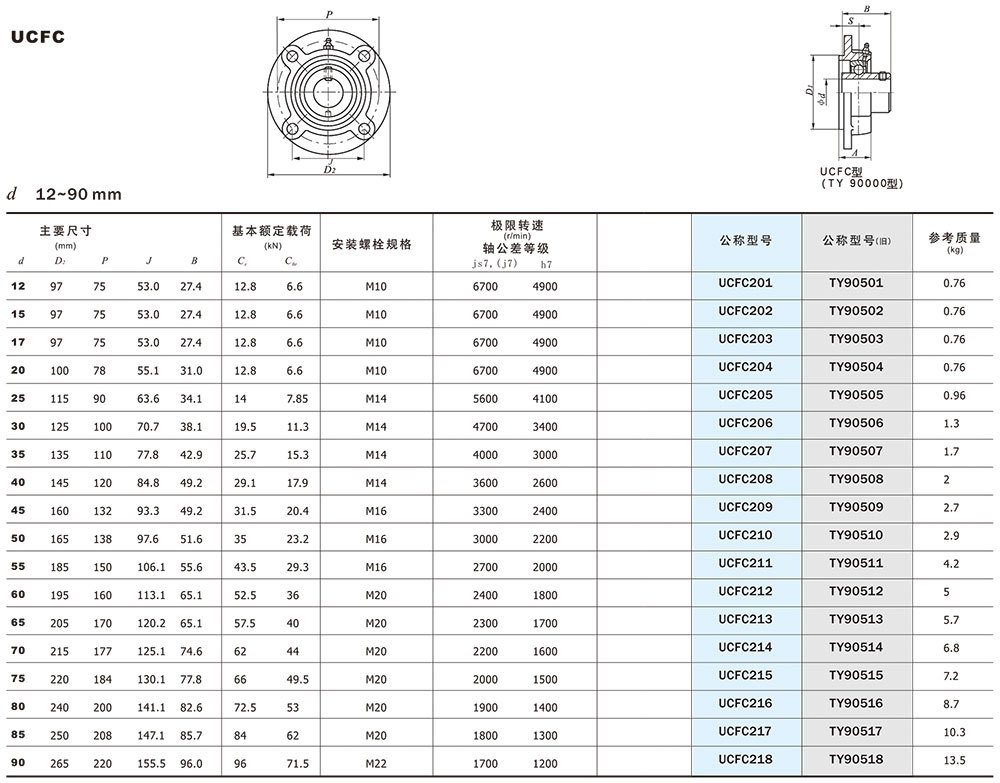

1. The main structural form of the outer spherical ball bearing

1. Top wire:

There are two types: UC type with wide inner ring and UB type with flat end of inner ring. Bearings with top screws are suitable for applications where the direction of rotation changes.

2. With eccentric sleeve:

There are two types: UEL type with wide inner ring and UE type with flat end of inner ring. Bearings with eccentric sleeves are suitable for applications where the direction of rotation does not change.

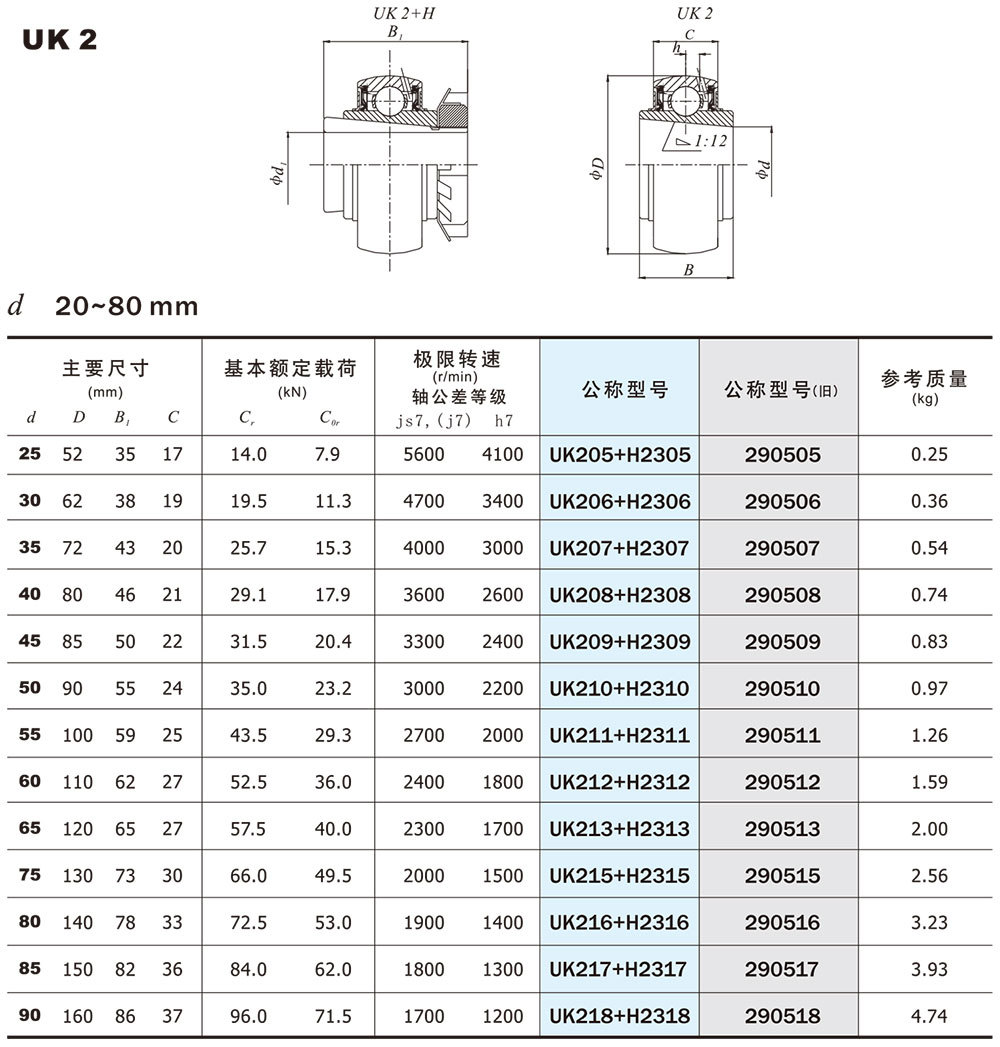

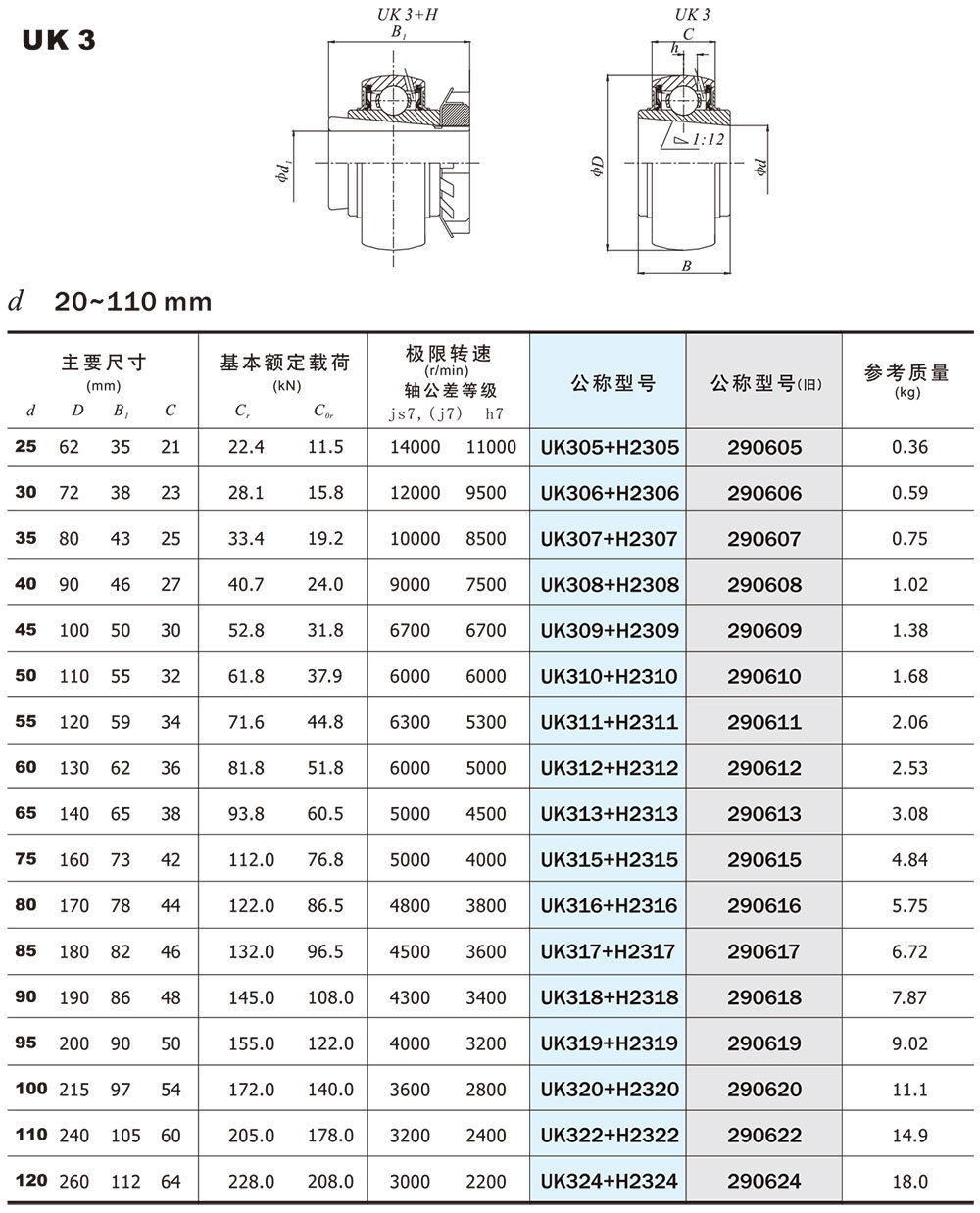

3. With adapter sleeve:

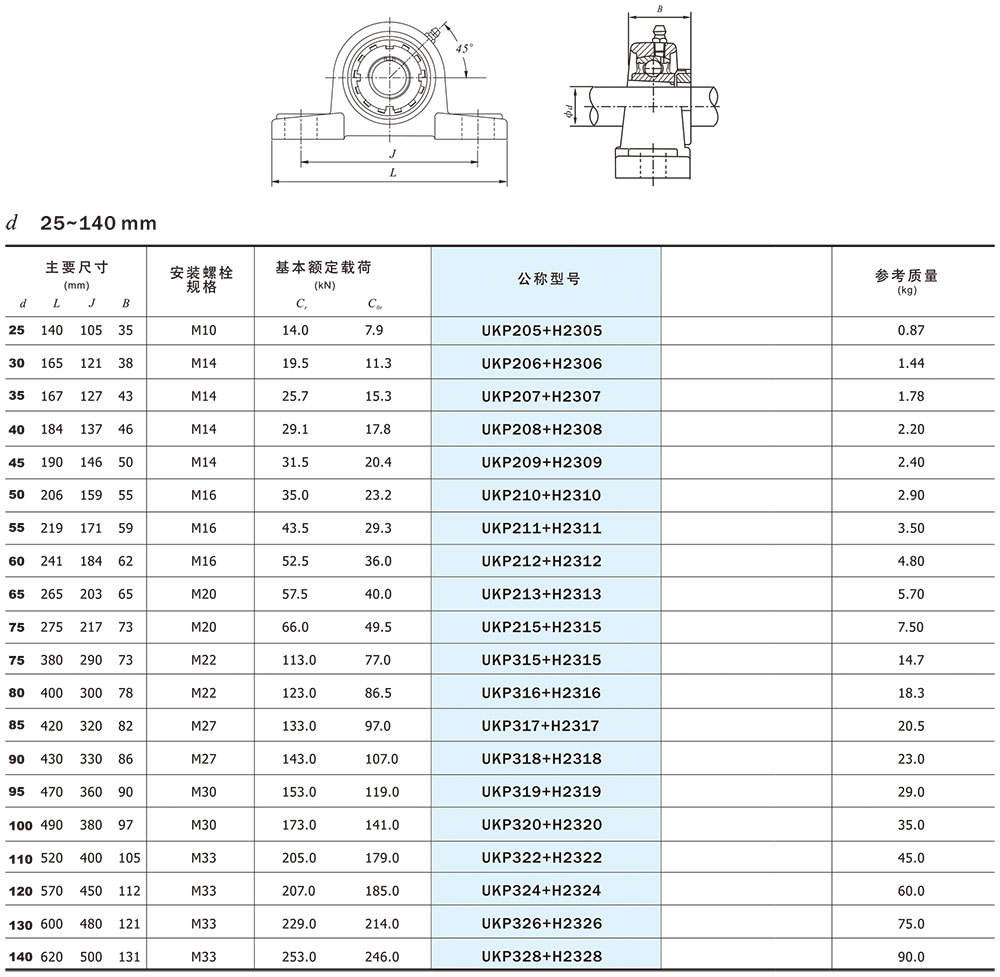

The UK+H type with wide inner ring and tapered inner diameter is suitable for occasions where the direction of rotation changes, the speed is high, and the operation is stable.

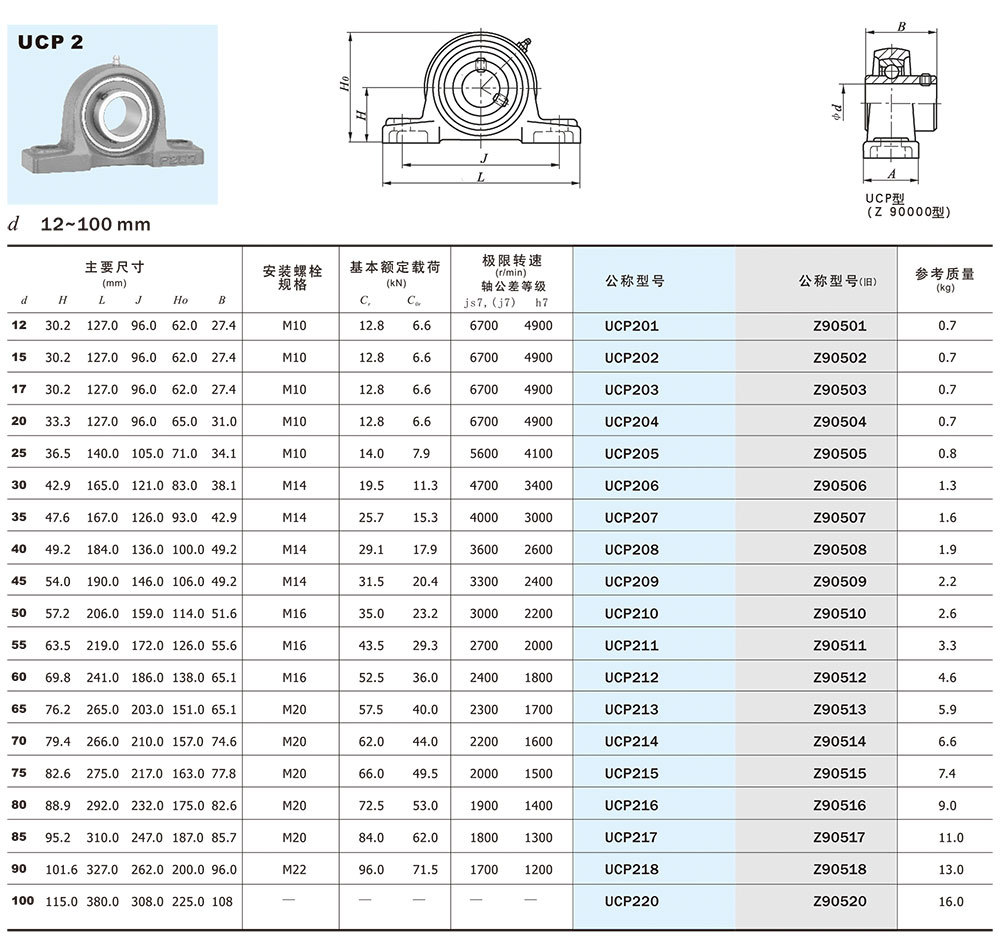

2. The main structural form of the bearing seat

The casting seat has various types such as vertical, square, rhombus, boss round, ring, slider seat and so on.

There are vertical, round, triangular, diamond and other types of stamping seats.

The same bearing with seat can be divided into various structural types according to the structural modification of its seat or the lubrication method and seal of the bearing.

3. Cage material

Basically the same as deep groove ball bearings.

4. Allowable inclination angle

The maximum allowable deflection between the outer spherical ball bearing and the central axis is generally 5°. If additional grease is required during use, the deflection angle is not allowed to exceed 2°.

5. Tolerance and Clearance

The tolerance of the inner ring of the outer spherical ball bearing is different from that of the deep groove ball bearing. Its value should meet the requirements of Table 1 or Table 2, the tolerance of the outer ring should meet the requirements of Table 3, and the dimensional tolerance of the eccentric sleeve should meet the requirements of Table 4. The radial clearance of spherical insert ball bearings is usually larger than that of deep groove ball bearings of the same size. The radial clearance value of spherical insert ball bearings with cylindrical bores shall comply with the provisions in Table 5. The radial clearance of insert spherical ball bearings with tapered bores The value should comply with the regulations in Table 6.

Table 1 Tolerance of Inner Ring of Cylindrical Bore

|

d(mm) |

∆dmp |

Vdp |

∆Hs |

∆Bs |

Kia |

||||

|

Exceed |

Arrive |

Upper deviation |

Lower deviation |

Maximum |

Upper deviation |

Lower deviation |

Upper deviation |

Lower deviation |

Maximum |

|

10 |

18 |

+15 |

0 |

10 |

+100 |

-100 |

0 |

-120 |

12 |

Note: The inner hole can be plated to reduce the corrosion of the bearing during operation. The tolerances listed in the table are applicable to the surface of the inner hole with or without plating.

Table 2 Tolerance of the inner ring of the tapered hole

|

d(mm) |

∆dmp |

∆d1mp—∆dmp |

|||

|

Exceed |

Arrive |

Upper deviation |

Lower deviation |

Upper deviation |

Lower deviation |

|

10 |

18 |

+27 |

0 |

+18 |

0 |

Table 3 Outer ring tolerance

|

D(mm) |

∆Dmp |

Kea |

||

|

Exceed |

Arrive |

Upper deviation |

Lower deviation |

Maximum |

|

30 |

50 |

0 |

-11 |

20 |

Note: The Lower deviation value of ∆Dmp is not applicable within 1/4 width from the end face of the outer ring.

Table 4 Eccentric sleeve

Unit:μm

|

d(mm ) |

∆ds |

∆d2s |

∆Hs |

∆B2s |

∆A1s |

||||||

|

Exceed |

Arrive |

Upper deviation |

Lower deviation |

Upper deviation |

Lower deviation |

Upper deviation |

Lower deviation |

Upper deviation |

Lower deviation |

Upper deviation |

Lower deviation |

|

10 |

35 |

+250 |

+25 |

+300 |

0 |

+100 |

-100 |

+270 |

-270 |

0 |

-180 |

Table 5 Cylindrical bore

Unit:μm

|

Bearing Nominal Inner Diameter |

2, 3 Series |

||||||

|

2 set |

0 set |

3 set |

|||||

|

Exceed |

Arrive |

The smallest |

Maximum |

The smallest |

Maximum |

The smallest |

Maximum |

|

10 |

18 |

3 |

18 |

10 |

25 |

18 |

33 |

Table 6 Tapered hole

Unit:μm

|

Bearing Nominal Inner Diameter |

2, 3 Series |

||||||

|

2 set |

0 set |

3 set |

|||||

|

Exceed |

Arrive |

The smallest |

Maximum |

The smallest |

Maximum |

The smallest |

Maximum |

|

10 |

18 |

10 |

25 |

18 |

33 |

25 |

45 |

6. Load capacity

The load capacity of the outer spherical ball bearing is basically the same as that of the deep groove ball bearing, and the calculation method of the equivalent load is also the same.

The load capacity of the outer spherical ball bearing with seat is also related to the type or fastening method of the seat. Cast outer spherical ball bearings can make full use of the bearing capacity of the bearing, but the axial load capacity depends on the degree of fastening between the inner ring of the bearing and the shaft. The axial load is not more than 20% of the rated dynamic load of Exceed. When the axial load is large, it is necessary to add a fastening device on the shaft, such as a shaft shoulder.

With top wire spherical ball bearing

Insert spherical ball bearing with adapter sleeve

Outer spherical ball bearing with vertical seat

Spherical ball bearing with vertical seat adapter sleeve

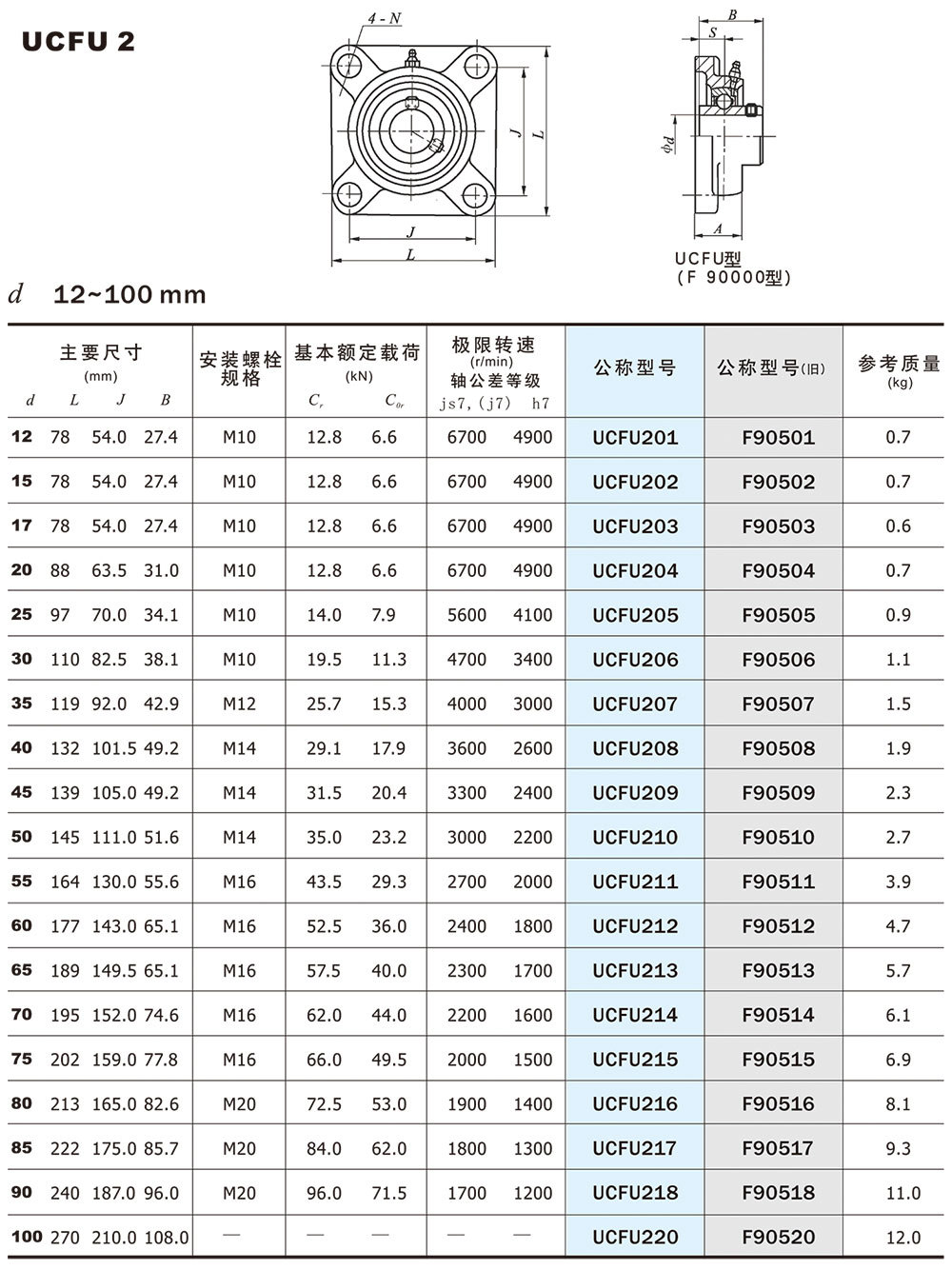

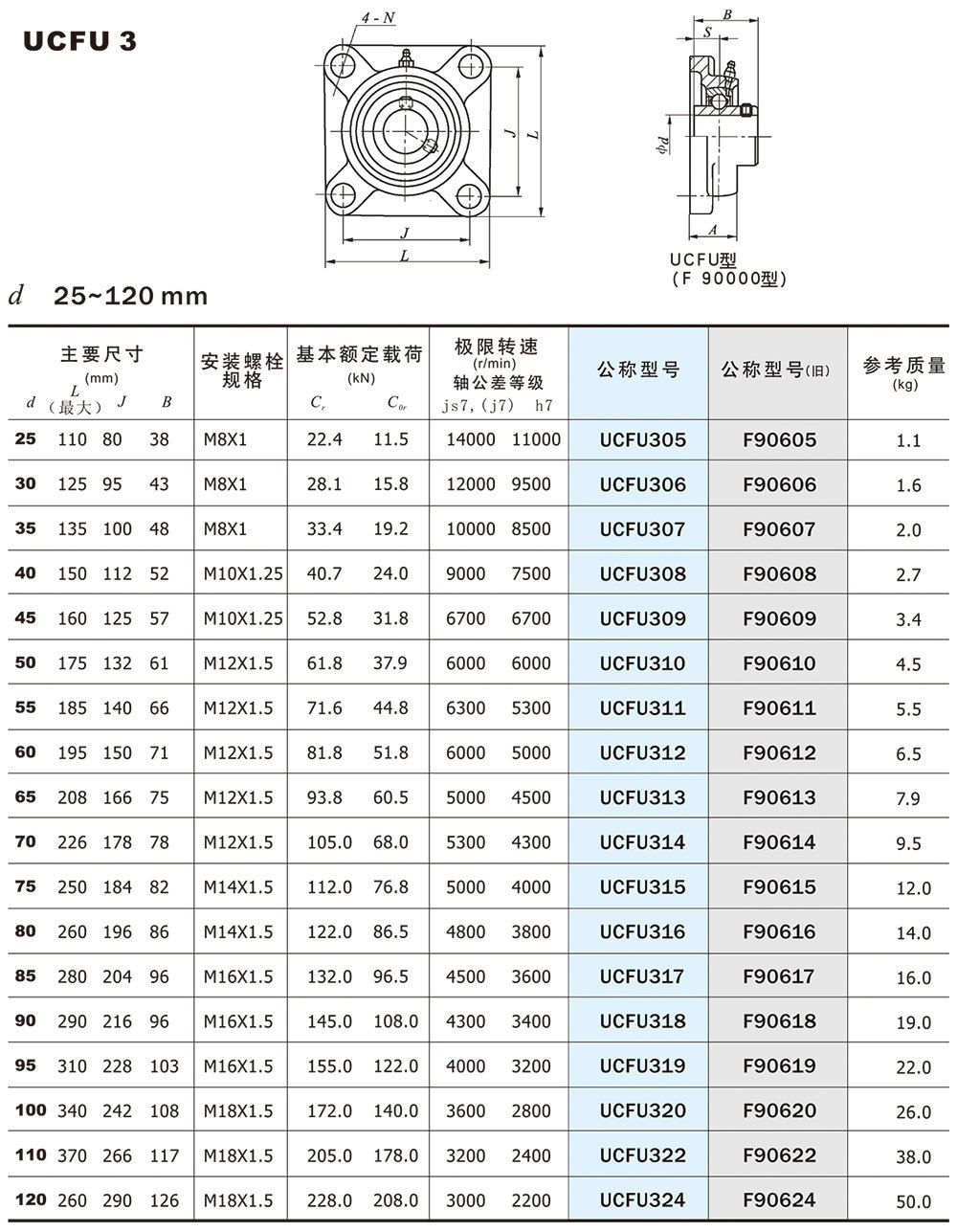

With square seat insert spherical ball bearing

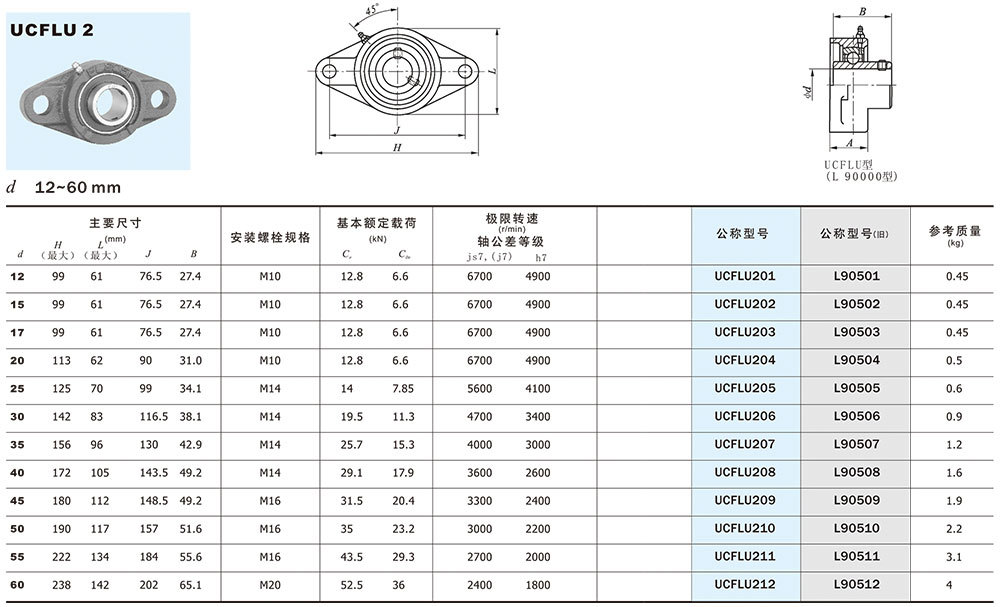

Insert spherical ball bearing with rhombic seat

Spherical ball bearing with slider seat

Outer spherical ball bearing with boss round seat

Type

Inside Diameter(mm)

Outside Diameter(mm)

Breadth(mm)

Weight(g)

Dynamic Load(N)

Static Load(N)

Supply From Stock

-

-

-

-

-

-

-

-

Factory

Previous Article

Next Article

Previous Article

Next Article

FAQ

Q

Are you a manufacturer?

A

Yes, we are a strong manufacturer.

Q

Can we visit your factory?

A

Of course, welcome to our factory for on-site inspection.

Q

Can we order samples?

A

Yes, we support customization.

Q

Can you arrange shipment? What are the physical methods?

A

Yes Can be arranged by sea shipping.

Q

What is your lead time?

A

Within 30 days after we confirm your request .

Q

What payment methods do you support?

A

T/T, 100% L/C at sight, Cash, Western Union are all accepted if you have other payment,please contact me.

Get a Free Quote

Series of Products