Spherical Roller Bearing

Payment Terms:

T/T

100% L/C

Cash

Western Union

Delivery Time:

30 Days

Keywords:

Series:

Product Details

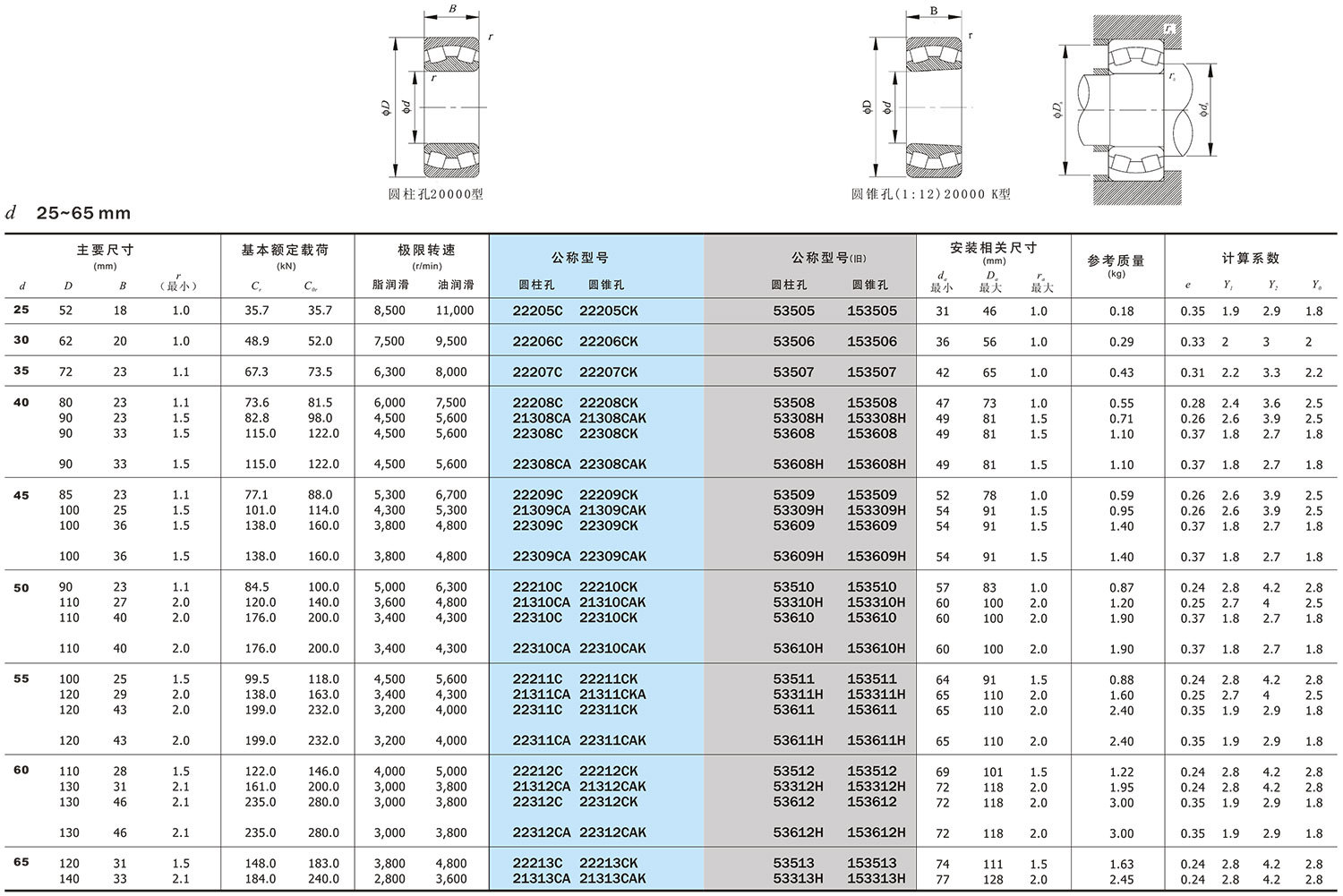

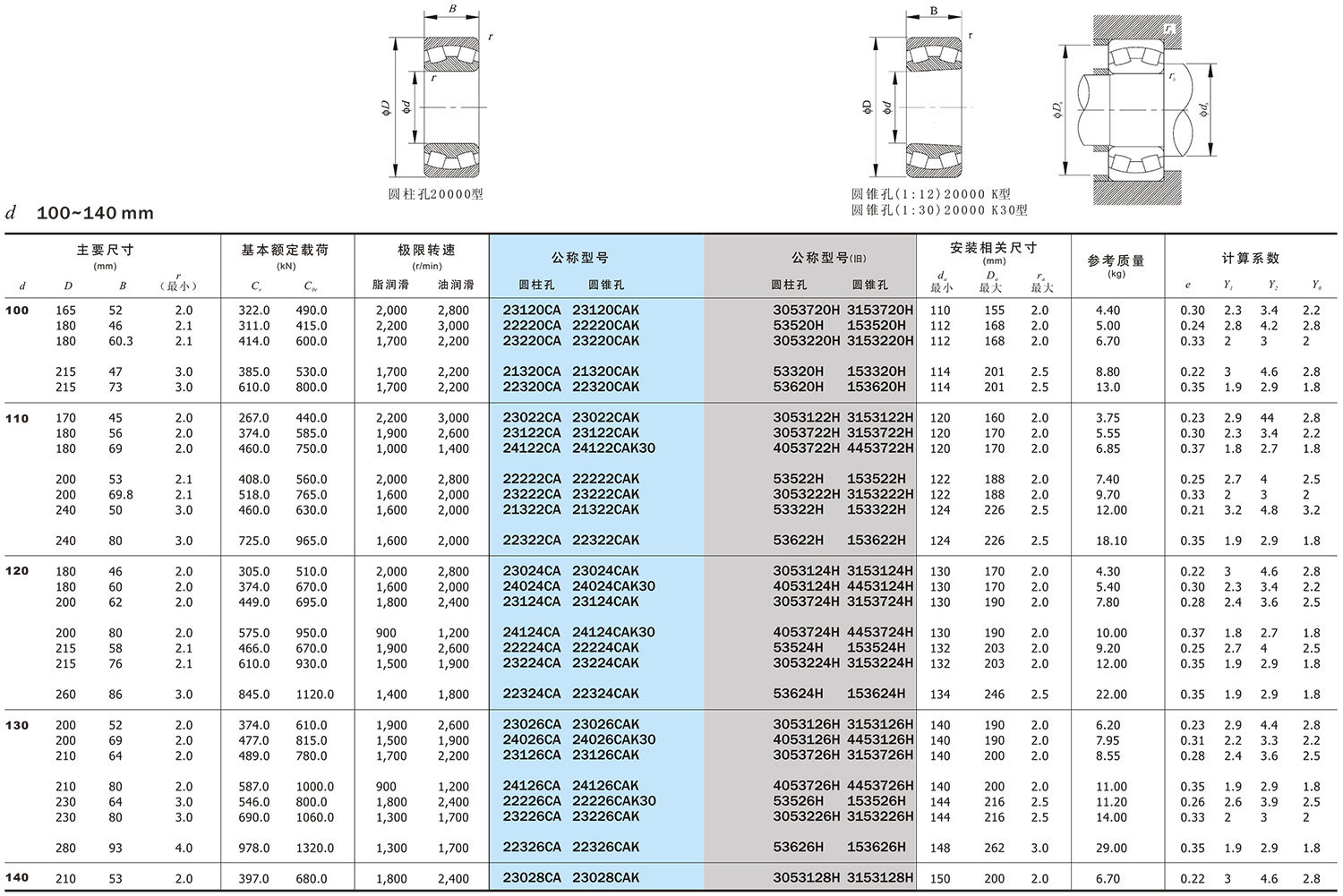

The spherical roller bearing has two rows of rollers, the outer ring is a spherical raceway, and the inner ring has two raceways inclined at a certain angle relative to the bearing axis. The bearings are self-aligning and are therefore less susceptible to misalignment of the shaft and housing and bending or deformation of the shaft. In addition to being able to bear high radial loads, spherical roller bearings can also bear axial loads acting in both directions.

Applications of self-aligning roller bearings: papermaking machinery, reduction gears, railway vehicle axles, rolling mill gearbox seats, rolling mill roller table rollers, crushers, vibrating screens, printing machinery, woodworking machinery, and various reducers.

C&U's spherical roller bearings are equipped with symmetrical large-diameter spherical rollers (reinforced type), capable of carrying extremely heavy loads. The internal design is slightly different according to the series and size. C&U can provide spherical roller bearings with C structure and CA structure.

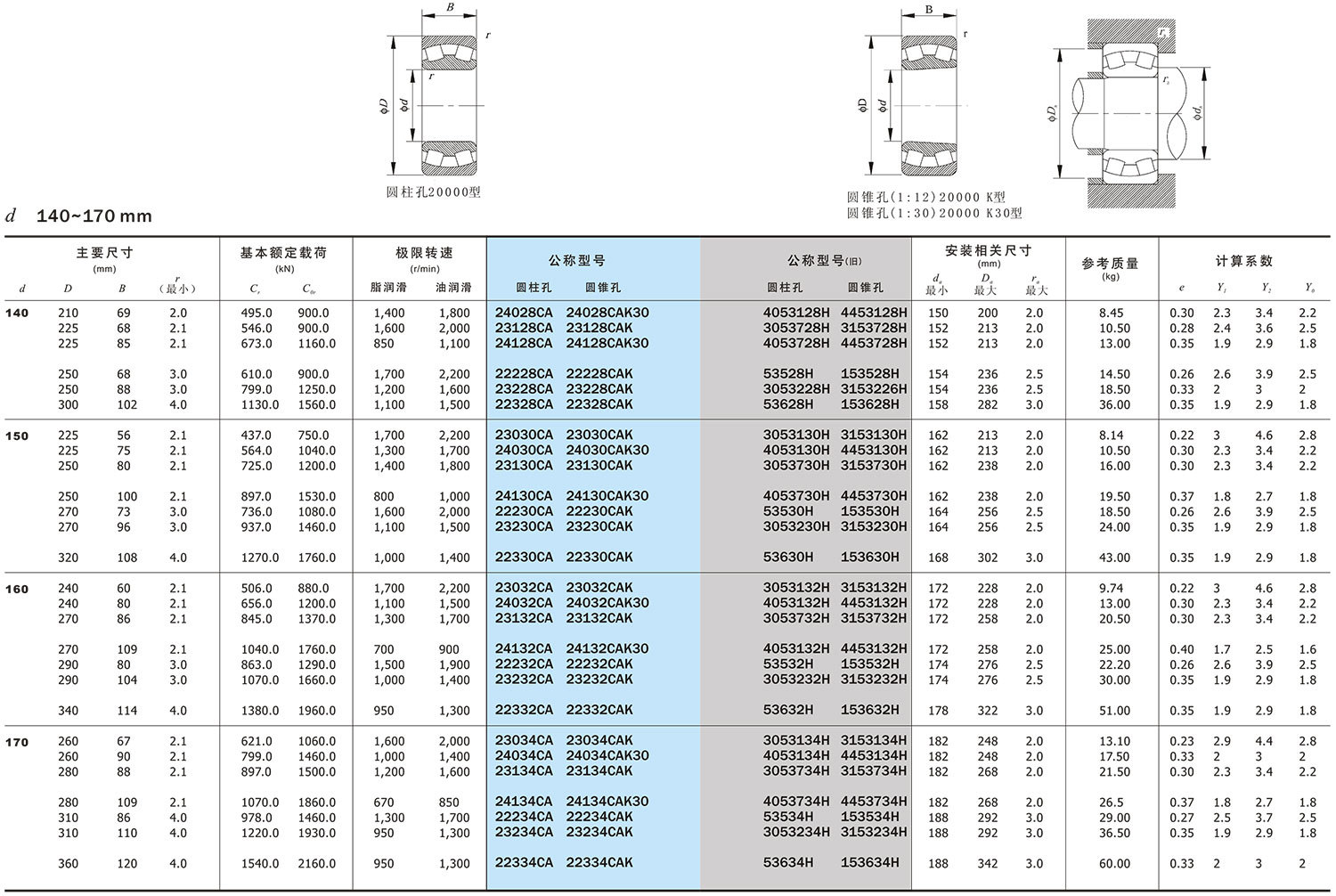

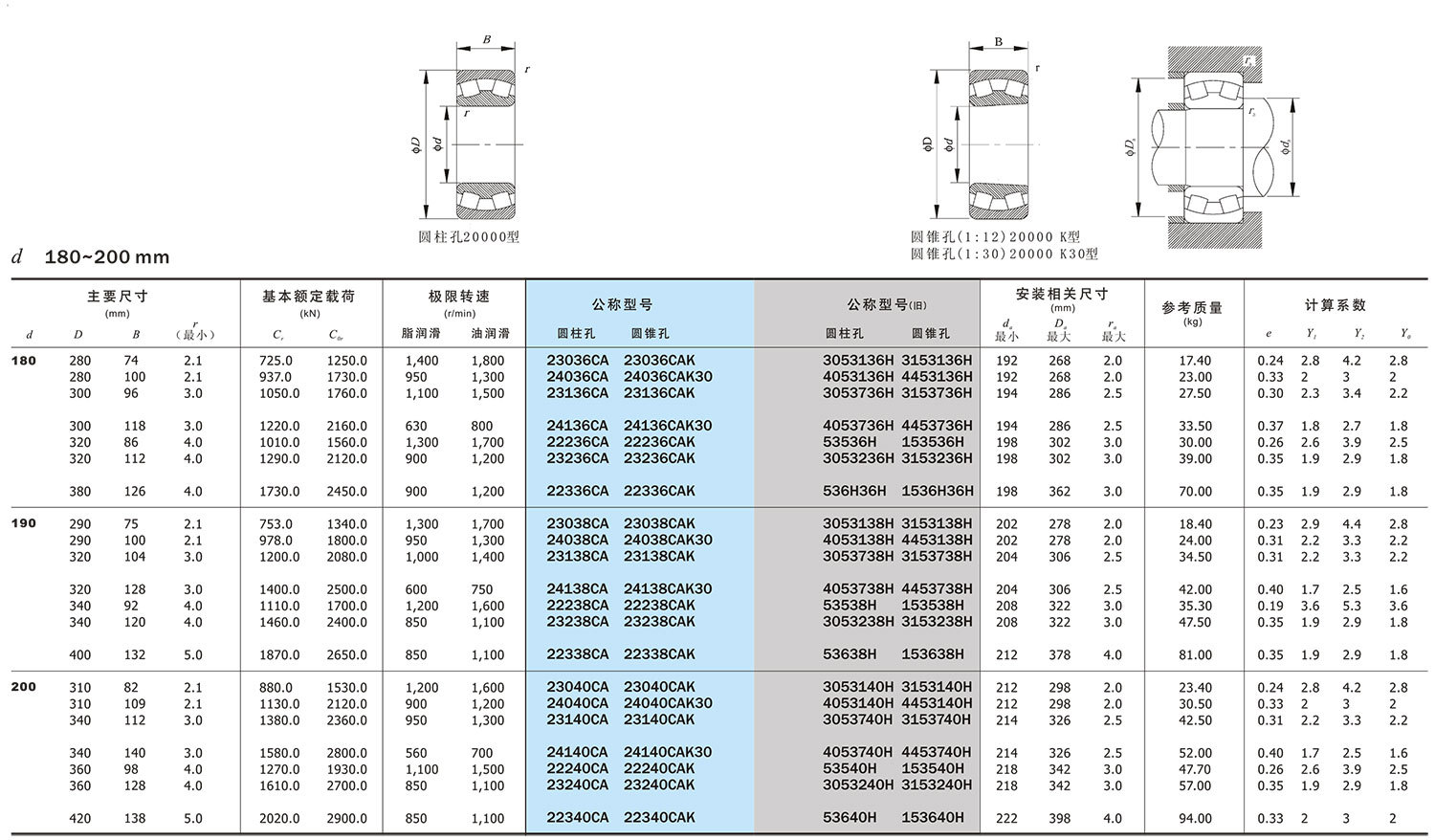

The inner diameter of the spherical roller bearing has a cylindrical bore and a tapered bore. The taper of the conical hole is 1:12 (the rear code is K), or the taper is 1:30 (the rear code is K30). C&U can provide spherical roller bearings with cylindrical holes or tapered holes on the inner diameter surface, and most series of C&U spherical roller bearings have tapered inner holes with a taper of 1:12 (the post code is K), only The inner hole taper of 24000 series and 24100 series spherical roller bearings is 1:30 (the rear code is K30).

In order to facilitate effective lubrication, the outer ring of spherical roller bearings can have lubricating oil grooves and lubricating oil holes. C&U can provide spherical roller bearings with lubricating oil grooves and lubricating oil holes in the outer ring. The dimensions and data of lubricating oil grooves and lubricating oil holes are not included in the following data sheets. Please consult the technical center of Renben Group when necessary.

C&U can also provide spherical roller bearings with seals. According to the working conditions and the internal structure of spherical roller bearings, there are corresponding sealing structures. If necessary, please consult the technology center of C&U Group.

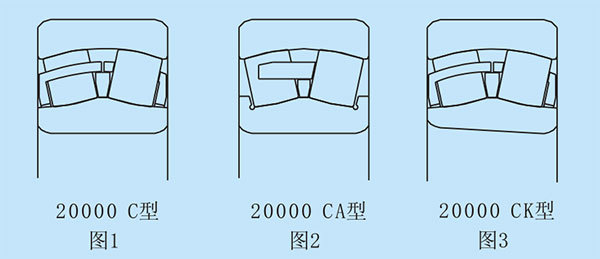

1. Structural form

1. 20000 Type C (Fig. 1): There are no ribs on both sides of the inner ring, movable intermediate ring, the rollers are symmetrical spherical rollers, the cage is 2 punched cages, and the inner diameter surface is a cylindrical surface;

2. Type 20000 CA (Fig. 2): There are ribs on both sides of the inner ring, the rollers are symmetrical spherical rollers, and the cage is a spherical roller bearing with a brass solid cage, and the inner diameter surface is a cylindrical surface;

3. 20000 CK type (Fig. 3): There are no ribs on both sides of the inner ring, movable intermediate ring, the rollers are symmetrical spherical rollers, and the cage is a self-aligning roller bearing with 2 stamped cages. The inner diameter is tapered. The taper is 1:12 (the rear code is K);

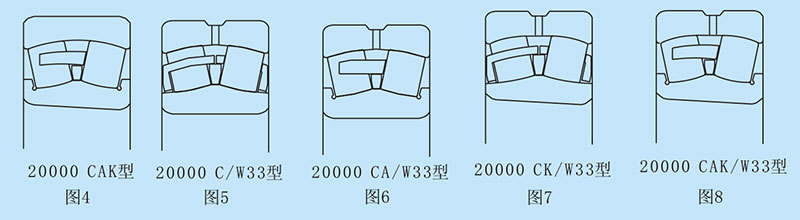

4. Type 20000 CAK (Fig. 4): There are ribs on both sides of the inner ring, the rollers are symmetrical spherical rollers, and the cage is a spherical roller bearing with a brass solid cage. The inner diameter surface is tapered, and the taper is 1 : 12 (the rear code is K), or the taper is 1:30 (the rear code is K30);

5. Type 20000 C/W33 (Fig. 5): There are no ribs on both sides of the inner ring, a movable intermediate ring, the rollers are symmetrical spherical rollers, and the cage is a self-aligning roller bearing with two stamping cages. The outer ring With lubricating oil groove and lubricating oil hole, the inner diameter surface is a cylindrical surface;

6. Type 20000 CA/W33 (Figure 6): The inner ring has ribs on both sides, the rollers are symmetrical spherical rollers, the cage is a spherical roller bearing with a brass solid cage, the outer ring has a lubricating oil groove and The lubricating oil hole has a taper on the inner diameter surface, the taper is 1:12 (the post code is K), or the taper is 1:30 (the post code is K30);

7. 20000 CK/W33 type (Fig. 7): There are no ribs on both sides of the inner ring, movable intermediate rings, rollers are symmetrical spherical rollers, cages are self-aligning roller bearings with 2 stamped cages, outer rings With lubricating oil groove and lubricating oil hole, the inner diameter surface has a taper, the taper is 1:12 (the rear code is K);

8. Type 20000 CAK/W33 (Figure 8): The inner ring has ribs on both sides, the rollers are symmetrical spherical rollers, the cage is a spherical roller bearing with a brass solid cage, the outer ring has a lubricating oil groove and The lubricating oil hole has a taper on the inner diameter surface, the taper is 1:12 (the post code is K), or the taper is 1:30 (the post code is K30).

2. Dimensional accuracy and rotation accuracy

Tolerances for radial bearings (except tapered roller bearings)

3. Radial clearance

C&U standard spherical roller bearings adopt common group clearance. In order to adapt to different working environments and installation requirements, C&U also provides large clearance self-aligning roller bearings, and C2 group clearance smaller than normal group clearance can also be supplied.

See Table 6.14 for radial clearance values for spherical roller bearings with cylindrical bores, and technical table 6.15 for radial clearance values for spherical roller bearings with tapered bores. These data are the clearance values without load before the bearing is installed.

Table 6.14 Radial clearance of spherical roller bearings (cylindrical bore)

Bearing Nominal Inner Diameter d(mm) | Clearance(μm) | ||||||||||

2 set | 0 set | 3 set | 4 set | 5 set | |||||||

Exceed | Arrive | The smallest | Maximum | The smallest | Maximum | The smallest | Maximum | The smallest | Maximum | The smallest | Maximum |

14 18 24 30 40 50 65 80 100 120 140 160 180 200 225 250 280 315 355 400 450 500 560 630 710 800 900 | 18 24 30 40 50 65 80 100 120 140 160 180 200 225 250 280 315 355 400 450 500 560 630 710 80 900 1000 | 10 10 15 15 20 20 30 35 40 50 60 65 70 80 90 100 110 120 130 140 140 150 170 190 210 230 260 | 20 20 25 30 35 40 50 60 75 95 110 120 130 140 150 170 190 200 220 240 260 280 310 350 390 430 480 | 20 20 25 30 35 40 50 60 75 95 110 120 130 140 150 170 190 200 220 240 260 280 310 350 390 430 480 | 35 35 40 45 55 65 80 100 120 145 170 180 200 220 240 260 280 310 340 370 410 440 480 530 580 650 710 | 35 35 40 45 55 65 80 100 120 145 170 180 200 220 240 260 280 310 340 370 410 440 480 530 580 650 710 | 45 45 55 60 75 90 110 135 160 190 220 240 260 290 320 350 370 410 450 500 550 600 650 700 770 860 930 | 45 45 55 60 75 90 110 135 160 190 220 240 260 290 320 350 370 410 450 500 550 600 650 700 770 860 930 | 60 60 75 80 100 120 145 180 210 240 280 310 340 380 420 460 500 550 600 660 720 780 850 920 1010 1120 1220 | 60 60 75 80 100 120 145 180 210 240 280 310 340 380 420 460 500 550 600 660 720 780 850 920 1010 1120 1220 | 75 75 95 100 125 150 180 225 260 300 350 390 430 470 520 570 630 690 750 820 900 1000 1100 1190 1300 1440 1570 |

Table 6.15 Radial Clearance of Spherical Roller Bearings (Tapered Bore)

Bearing Nominal Inner Diameter d(mm) | 游隙(μm) | ||||||||||

2 set | 0 set | 3 set | 4 set | 5 set | |||||||

Exceed | Arrive | The smallest | Maximum | The smallest | Maximum | The smallest | Maximum | The smallest | Maximum | The smallest | Maximum |

18 24 30 40 50 65 80 100 120 140 160 180 200 225 250 280 315 355 400 450 500 560 630 710 800 900 | 24 30 40 50 65 80 100 120 140 160 180 200 225 250 280 315 355 400 450 500 560 630 710 800 900 1000 | 15 20 25 30 40 50 55 65 80 90 100 110 120 140 150 170 190 210 230 260 290 320 350 390 440 490 | 25 30 35 45 55 70 80 100 120 130 140 160 180 200 220 240 270 300 330 370 410 460 510 570 640 710 | 25 30 35 45 55 70 80 100 120 130 140 160 180 200 220 240 270 300 330 370 410 460 510 570 640 710 | 35 40 50 60 75 95 110 135 160 180 200 220 250 270 300 330 360 400 440 490 540 600 670 750 840 930 | 35 40 50 60 75 95 110 135 160 180 200 220 250 270 300 330 360 400 440 490 540 600 670 750 840 930 | 45 55 65 80 95 120 140 170 200 230 260 290 320 350 390 430 470 520 570 630 680 760 850 960 1070 1190 | 45 55 65 80 95 120 140 170 200 230 260 290 320 350 390 430 470 520 570 630 680 760 850 960 1070 1190 | 65 75 85 100 120 150 180 220 260 300 340 370 410 450 490 540 590 650 720 790 870 980 1090 1220 1370 1520 | 65 75 85 100 120 150 180 220 260 300 340 370 410 450 490 540 590 650 720 790 870 980 1090 1220 1370 1520 | 75 95 105 130 160 200 230 280 330 380 430 470 520 570 620 680 740 820 910 1000 1100 1230 1360 1500 1690 1680 |

4. Cage

The C-type structure spherical roller bearing adopts steel stamping cage, and the CA-type structure spherical roller bearing adopts brass solid cage.

5. Allowable alignment angle

The internal structure design of the self-aligning roller bearing enables it to have an automatic self-aligning function, that is, the bearing itself can adjust the angular alignment error between the inner and outer rings. Under normal load and working conditions, when the inner ring rotates, the non-concentric angle values given in the table below are allowed. Whether or not the given value of Arrive can be fully achieved depends on conditions such as the design of the bearing arrangement and the type of seal.

Bearing series | Allowable non-concentric angle value |

21300 Series | 1° |

22200 Series | 1.5° |

22300 Series | 2° |

23000 Series | 1.5° |

23100 Series | 1.5° |

23200 Series | 2.5° |

24000 Series | 2° |

24100 Series | 2.5° |

6. Equivalent dynamic load

When Fₐ/Fᵣ<e P=Fᵣ+Y₁Fₐ

When Fₐ/Fᵣ>e P=0.67Fᵣ+Y₂Fₐ

The corresponding calculation coefficients e, Y₁, and Y₂ of each Arrive bearing can be found in the dimension table.

7. Equivalent static load

P₀=Fᵣ+Y₀Fₐ

Values for the Y₀ factor are given for each bearing in the dimension tables.

Spherical roller bearing

Type

Inside Diameter(mm)

Outside Diameter(mm)

Breadth(mm)

Weight(g)

Dynamic Load(N)

Static Load(N)

Supply From Stock

-

-

-

-

-

-

-

-

Factory

Previous Article

Next Article

Previous Article

Next Article

FAQ

Q

Are you a manufacturer?

A

Yes, we are a strong manufacturer.

Q

Can we visit your factory?

A

Of course, welcome to our factory for on-site inspection.

Q

Can we order samples?

A

Yes, we support customization.

Q

Can you arrange shipment? What are the physical methods?

A

Yes Can be arranged by sea shipping.

Q

What is your lead time?

A

Within 30 days after we confirm your request .

Q

What payment methods do you support?

A

T/T, 100% L/C at sight, Cash, Western Union are all accepted if you have other payment,please contact me.

Get a Free Quote

Series of Products